Page 27 - Orlicky's Material Requirements Planning

P. 27

8 PART 1 Perspective

The focus of this book is on the new rules required to effectively support a manu-

facturing operation using material requirements planning systems in the twenty-first

century. The objective is an exposition of procedural logic, function, and use of these sys-

tems rather than programming and other considerations of system implementation. All

considerations that are of a purely technical data-processing nature are excluded because

they are amply documented in manuals published by computer manufacturers and soft-

ware providers. The software aspect of MRP is intentionally downplayed so as not to

divert the reader’s attention from the really important subject matter. As far as MRP is

concerned, the computer’s contribution lies solely in its power to execute a host of rather

straightforward calculations in a very short time and display nearly instantaneous visi-

bility to relevant information and priorities to the appropriate personnel. A comprehen-

sive understanding of the computer aspect is not essential to an understanding of the

subject in question.

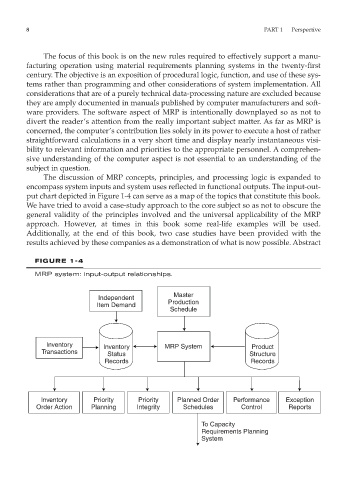

The discussion of MRP concepts, principles, and processing logic is expanded to

encompass system inputs and system uses reflected in functional outputs. The input-out-

put chart depicted in Figure 1-4 can serve as a map of the topics that constitute this book.

We have tried to avoid a case-study approach to the core subject so as not to obscure the

general validity of the principles involved and the universal applicability of the MRP

approach. However, at times in this book some real-life examples will be used.

Additionally, at the end of this book, two case studies have been provided with the

results achieved by these companies as a demonstration of what is now possible. Abstract

FIGURE 1-4

MRP system: input-output relationships.

Master

Independent

Item Demand Production

Schedule

Inventory Inventory MRP System Product

Transactions Status Structure

Records Records

Inventory Priority Priority Planned Order Performance Exception

Order Action Planning Integrity Schedules Control Reports

To Capacity

Requirements Planning

System