Page 130 - Petroleum and Gas Field Processing

P. 130

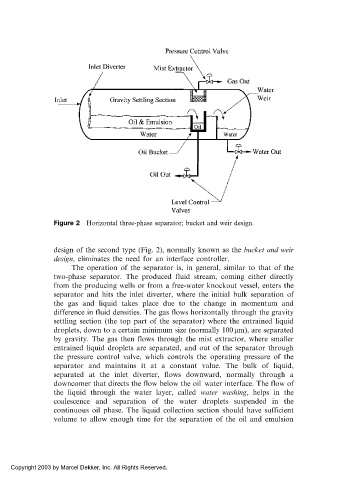

Figure 2 Horizontal three-phase separator; bucket and weir design.

design of the second type (Fig. 2), normally known as the bucket and weir

design, eliminates the need for an interface controller.

The operation of the separator is, in general, similar to that of the

two-phase separator. The produced fluid stream, coming either directly

from the producing wells or from a free-water knockout vessel, enters the

separator and hits the inlet diverter, where the initial bulk separation of

the gas and liquid takes place due to the change in momentum and

difference in fluid densities. The gas flows horizontally through the gravity

settling section (the top part of the separator) where the entrained liquid

droplets, down to a certain minimum size (normally 100 mm), are separated

by gravity. The gas then flows through the mist extractor, where smaller

entrained liquid droplets are separated, and out of the separator through

the pressure control valve, which controls the operating pressure of the

separator and maintains it at a constant value. The bulk of liquid,

separated at the inlet diverter, flows downward, normally through a

downcomer that directs the flow below the oil–water interface. The flow of

the liquid through the water layer, called water washing, helps in the

coalescence and separation of the water droplets suspended in the

continuous oil phase. The liquid collection section should have sufficient

volume to allow enough time for the separation of the oil and emulsion

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.