Page 132 - Petroleum and Gas Field Processing

P. 132

It is advisable to have the oil bucket as deep as possible and to have either

the oil weir, or the water weir, or both to be adjustable to accommodate

any unexpected changes in flow rates and/or liquids properties. Such

problems are easily accommodated in the interface controller and weir

design of Fig. 1, as the interface controller could be easily adjusted. In

some cases, however, when the difference in density between the water and

oil, or the water and emulsion are small (e.g., in heavy oil operations), the

operation of the interface controller becomes unreliable and the bucket

design (Fig. 2) will be preferred.

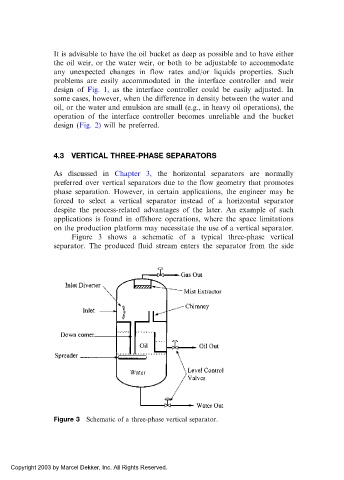

4.3 VERTICAL THREE-PHASE SEPARATORS

As discussed in Chapter 3, the horizontal separators are normally

preferred over vertical separators due to the flow geometry that promotes

phase separation. However, in certain applications, the engineer may be

forced to select a vertical separator instead of a horizontal separator

despite the process-related advantages of the later. An example of such

applications is found in offshore operations, where the space limitations

on the production platform may necessitate the use of a vertical separator.

Figure 3 shows a schematic of a typical three-phase vertical

separator. The produced fluid stream enters the separator from the side

Figure 3 Schematic of a three-phase vertical separator.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.