Page 214 - Petroleum and Gas Field Processing

P. 214

Hydrogen sulfide is normally the major sour component having

a vapor pressure greater than propane but less than ethane.

Normal stage separation will, therefore, liberate ethane and

propane from the stock tank liquid along with hydrogen sulfide.

Stripping efficiency of the system can be improved by mixing a

lean (sweet) stripping gas along with the separator liquid between

each separation stage.

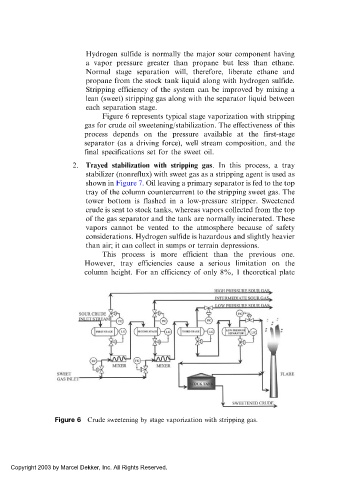

Figure 6 represents typical stage vaporization with stripping

gas for crude oil sweetening/stabilization. The effectiveness of this

process depends on the pressure available at the first-stage

separator (as a driving force), well stream composition, and the

final specifications set for the sweet oil.

2. Trayed stabilization with stripping gas. In this process, a tray

stabilizer (nonreflux) with sweet gas as a stripping agent is used as

shown in Figure 7. Oil leaving a primary separator is fed to the top

tray of the column countercurrent to the stripping sweet gas. The

tower bottom is flashed in a low-pressure stripper. Sweetened

crude is sent to stock tanks, whereas vapors collected from the top

of the gas separator and the tank are normally incinerated. These

vapors cannot be vented to the atmosphere because of safety

considerations. Hydrogen sulfide is hazardous and slightly heavier

than air; it can collect in sumps or terrain depressions.

This process is more efficient than the previous one.

However, tray efficiencies cause a serious limitation on the

column height. For an efficiency of only 8%, 1 theoretical plate

Figure 6 Crude sweetening by stage vaporization with stripping gas.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.