Page 29 - Petroleum and Gas Field Processing

P. 29

The drilling program consists of three main stages: (1) drilling the

hole to the target depth, (2) setting the various casings, and (3) cementing

the casing.

1.6.1 Drilling the Well

Well drilling has gone through major developments of drilling methods to

reach the modern method of rotary drilling. In this method, a drilling bit is

attached to the bottom end of a string of pipe joints known as the drilling

string. The drilling string is rotated at the surface, causing rotation of the

drilling bit. The rotation of the bit and the weight applied on it through

the drilling string causes the crushing and cutting of the rock into small

pieces (cuttings). To remove the cuttings from the hole, a special fluid,

called the drilling fluid or the drilling mud, is pumped down through the

drilling string, where it exists through nozzles in the bit as jets of fluid.

This fluid cleans the bit from the cuttings and carries the cuttings to the

surface through the annular space between the drilling string and the wall

of the hole. At the surface, the mud is screened to remove the cuttings and

is circulated back into the drilling string. The drilling operation is

performed using huge and complex equipment known as the drilling rig.

This is briefly described next.

The Drilling Rig

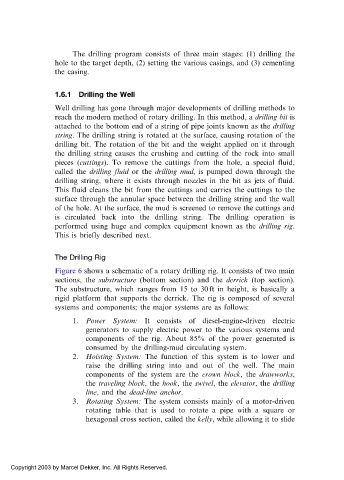

Figure 6 shows a schematic of a rotary drilling rig. It consists of two main

sections, the substructure (bottom section) and the derrick (top section).

The substructure, which ranges from 15 to 30 ft in height, is basically a

rigid platform that supports the derrick. The rig is composed of several

systems and components; the major systems are as follows:

1. Power System: It consists of diesel-engine-driven electric

generators to supply electric power to the various systems and

components of the rig. About 85% of the power generated is

consumed by the drilling-mud circulating system.

2. Hoisting System: The function of this system is to lower and

raise the drilling string into and out of the well. The main

components of the system are the crown block, the drawworks,

the traveling block, the hook, the swivel, the elevator, the drilling

line, and the dead-line anchor.

3. Rotating System: The system consists mainly of a motor-driven

rotating table that is used to rotate a pipe with a square or

hexagonal cross section, called the kelly, while allowing it to slide

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.