Page 83 - Petroleum and Gas Field Processing

P. 83

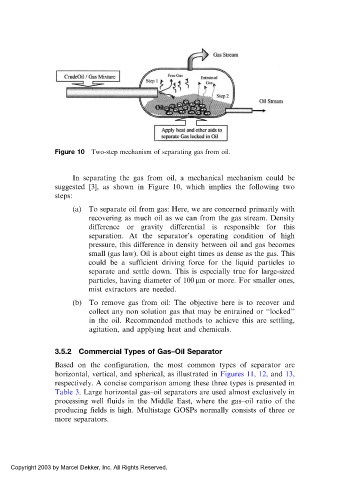

Figure 10 Two-step mechanism of separating gas from oil.

In separating the gas from oil, a mechanical mechanism could be

suggested [3], as shown in Figure 10, which implies the following two

steps:

(a) To separate oil from gas: Here, we are concerned primarily with

recovering as much oil as we can from the gas stream. Density

difference or gravity differential is responsible for this

separation. At the separator’s operating condition of high

pressure, this difference in density between oil and gas becomes

small (gas law). Oil is about eight times as dense as the gas. This

could be a sufficient driving force for the liquid particles to

separate and settle down. This is especially true for large-sized

particles, having diameter of 100 mm or more. For smaller ones,

mist extractors are needed.

(b) To remove gas from oil: The objective here is to recover and

collect any non solution gas that may be entrained or ‘‘locked’’

in the oil. Recommended methods to achieve this are settling,

agitation, and applying heat and chemicals.

3.5.2 Commercial Types of Gas–Oil Separator

Based on the configuration, the most common types of separator are

horizontal, vertical, and spherical, as illustrated in Figures 11, 12, and 13,

respectively. A concise comparison among these three types is presented in

Table 3. Large horizontal gas–oil separators are used almost exclusively in

processing well fluids in the Middle East, where the gas–oil ratio of the

producing fields is high. Multistage GOSPs normally consists of three or

more separators.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.