Page 38 - Pipeline Pigging Technology

P. 38

Available on-line technology

Services Association (PPSA). PPSA is a relatively-new body which, it is hoped,

will help to establish industry standards for III world-wide.

With the exception of one or two recent introductions, all the ILI tools

currently available were described in a previous paper [1], and a list of

manufacturers of each type is shown in Fig. 1. Further details are also available

from the PPSA.

Each of these tools is often very different, and they are so highly specialized

that, without exception, they are not sold, but are used by their manufacturer

to carry out the inspection on behalf of the operator.

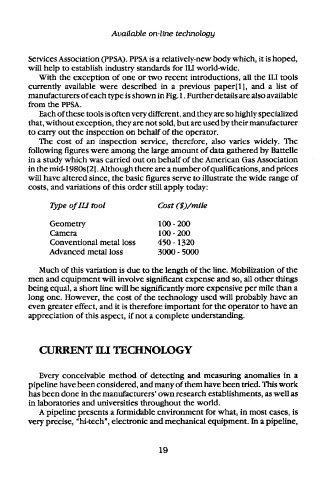

The cost of an inspection service, therefore, also varies widely. The

following figures were among the large amount of data gathered by Battelle

in a study which was carried out on behalf of the American Gas Association

in the mid-1980s [2]. Although there are a number of qualifications, and prices

will have altered since, the basic figures serve to illustrate the wide range of

costs, and variations of this order still apply today:

Type of ILI tool Cost ($)/mite

Geometry 100 - 200

Camera 100-200

Conventional metal loss 450 -1320

Advanced metal loss 3000 - 5000

Much of this variation is due to the length of the line. Mobilization of the

men and equipment will involve significant expense and so, all other things

being equal, a short line will be significantly more expensive per mile than a

long one. However, the cost of the technology used will probably have an

even greater effect, and it is therefore important for the operator to have an

appreciation of this aspect, if not a complete understanding.

CURRENT ILI TECHNOLOGY

Every conceivable method of detecting and measuring anomalies in a

pipeline have been considered, and many of them have been tried. This work

has been done in the manufacturers' own research establishments, as well as

in laboratories and universities throughout the world.

A pipeline presents a formidable environment for what, in most cases, is

very precise, "hi-tech", electronic and mechanical equipment. In a pipeline,

19