Page 405 - Pipeline Pigging Technology

P. 405

Pipeline Pigging Technology

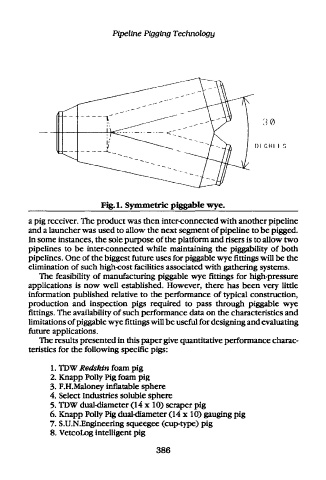

Fig.l. Symmetric piggable wye.

a pig receiver. The product was then inter-connected with another pipeline

and a launcher was used to allow the next segment of pipeline to be pigged.

In some instances, the sole purpose of the platform and risers is to allow two

pipelines to be inter-connected while maintaining the piggability of both

pipelines. One of the biggest future uses for piggable wye fittings will be the

elimination of such high-cost facilities associated with gathering systems.

The feasibility of manufacturing piggable wye fittings for high-pressure

applications is now well established. However, there has been very little

information published relative to the performance of typical construction,

production and inspection pigs required to pass through piggable wye

fittings. The availability of such performance data on the characteristics and

limitations of piggable wye fittings will be useful for designing and evaluating

future applications.

The results presented in this paper give quantitative performance charac-

teristics for the following specific pigs:

1. TDW Redskin foam pig

2. Knapp Polly Pig foam pig

3. F.H.Maloney inflatable sphere

4. Select Industries soluble sphere

5. TDW dual-diameter (14 x 10) scraper pig

6. Knapp Polly Pig dual-diameter (14 x 10) gauging pig

7. S.U.N.Engineering squeegee (cup-type) pig

8. VetcoLog intelligent pig

386