Page 406 - Pipeline Pigging Technology

P. 406

Pigging through Y fittings

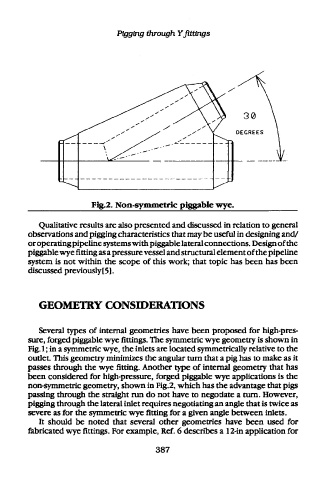

Fig.2. Non-symmetric piggable wye.

Qualitative results are also presented and discussed in relation to general

observations and pigging characteristics that may be useful in designing and/

or operating pipeline systems with piggable lateral connections. Design of the

piggable wye fitting as a pressure vessel and structural element of the pipeline

system is not within the scope of this work; that topic has been has been

discussed previously[5].

GEOMETRY CONSIDERATIONS

Several types of internal geometries have been proposed for high-pres-

sure, forged piggable wye fittings. The symmetric wye geometry is shown in

Fig. 1; in a symmetric wye, the inlets are located symmetrically relative to the

outlet. This geometry minimizes the angular turn that a pig has to make as it

passes through the wye fitting. Another type of internal geometry that has

been considered for high-pressure, forged piggable wye applications is the

non-symmetric geometry, shown in Fig.2, which has the advantage that pigs

passing through the straight run do not have to negotiate a turn. However,

pigging through the lateral inlet requires negotiating an angle that is twice as

severe as for the symmetric wye fitting for a given angle between inlets.

It should be noted that several other geometries have been used for

fabricated wye fittings. For example, Ref. 6 describes a 12-in application for

387