Page 445 - Pipeline Pigging Technology

P. 445

Pipeline Pigging Technology

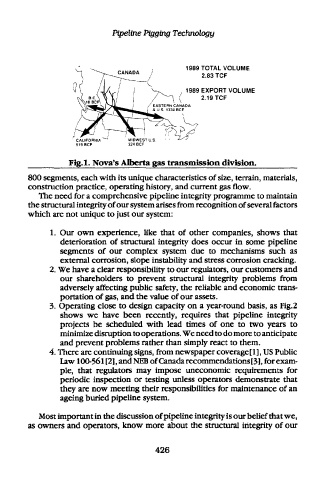

Fig.l. Nova's Alberta gas transmission division.

800 segments, each with its unique characteristics of size, terrain, materials,

construction practice, operating history, and current gas flow.

The need for a comprehensive pipeline integrity programme to maintain

the structural integrity of our system arises from recognition of several factors

which are not unique to just our system:

1. Our own experience, like that of other companies, shows that

deterioration of structural integrity does occur in some pipeline

segments of our complex system due to mechanisms such as

external corrosion, slope instability and stress corrosion cracking.

2. We have a clear responsibility to our regulators, our customers and

our shareholders to prevent structural integrity problems from

adversely affecting public safety, the reliable and economic trans-

portation of gas, and the value of our assets.

3. Operating close to design capacity on a year-round basis, as Fig.2

shows we have been recently, requires that pipeline integrity

projects be scheduled with lead times of one to two years to

minimize disruption to operations. We need to do more to anticipate

and prevent problems rather than simply react to them.

4. There are continuing signs, from newspaper coverage [1], US Public

Law 100-561 [2], and NEB of Canada recommendations [3], for exam-

ple, that regulators may impose uneconomic requirements for

periodic inspection or testing unless operators demonstrate that

they are now meeting their responsibilities for maintenance of an

ageing buried pipeline system.

Most important in the discussion of pipeline integrity is our belief that we,

as owners and operators, know more about the structural integrity of our

426