Page 404 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 404

.

Appendix G1379

Appendix G

Examples of

Common Pipeline

Inspection and

Survey Techniques

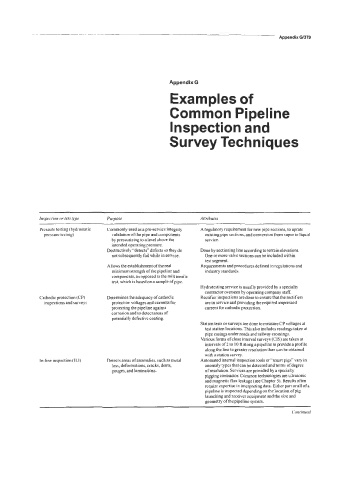

Inspection or test ppe Purpose Attributes

Pressure testing (hydrostatic Commonly used as a pre-service integrity A regulatory requirement for new pipe sections, to uprate

pressure testing) validation ofthe pipe and components existing pipe sections. and conversion from vapor to liquid

by pressurizing to a level above the service.

intended operating pressure.

Destructively “detects” defects so they do Done by sectioning line according to terrain elevations.

not subsequently fail while in service. One or more valve sections can be included within

test segment.

Allows the establishment ofthe real Requirements and procedures defined in regulations and

minimum strength ofthe pipeline and industry standards.

components, as opposed to the mill tensile

test, which is based on a sample ofpipe.

Hydrotesting service is usually provided by a specialty

contractor overseen by operating company staff.

Cathodic protection (CP) Determines the adequacy of cathodic Rectifier inspections are done to ensure that the rectifiers

inspections and surveys protection voltages and currents for are in service and providing the required impressed

protecting the pipeline against current for cathodic protection.

corrosion and to detect areas of

potentially defective coating.

Station tests or surveys are done to measure CP voltages at

test station locations. This also includes readings taken at

pipe casings under roads and railway crossings.

Various forms ofclose interval surveys (CIS) are taken at

intervals of 2 to IO ft along a pipeline to provide a profile

along the line to greater resolution than can be obtained

with a station survey.

In-line inspection (ILI) Detects areas of anomalies, such as metal Automated internal inspection tools or “smart pigs” vary in

loss, deformations, cracks, dents, anomaly types that can be detected and terms of degree

gouges, and laminations. ofresolution. Services are provided by a specialty

pigging contractor. Common technologles are ultrasonic

and magnetic flux leakage (see Chapter 5). Results often

require expertise in interpreting data. Either part or all of a

pipeline is inspected depending on the location of pig

launching and receiver equipment and the size and

geometry of the pipeline system.

Continued