Page 151 - Pipelines and Risers

P. 151

124 Chapter 9

9.2.4 Vibration Amplitude and Stress Range Analysis

The results of the structural and environmental analysis are used as input to the calculation of

the response of the free span to the environmental loads.

The response may be found through the application of static or quasi-static loads or may be

given directly as vibration amplitudes.

Due to the complexity of the physical processes involved, Le. the highly non-linear nature of

the fluid-elastic interaction of the vibrating span, the response of the span will generally be

determined through the application of model or full scale investigation.

Therefore the fluid-elastic properties of the environmental and the free span will be described

by a number of governing non-dimensional parameters which are used to retrieve the relevant

response data (force coefficients and oscillation amplitudes).

The response data are subsequently used to calculate:

Stress range distribution

Expected number of oscillations

Fatigue damages parameter

Maximum stress

9.2.5 Fatigue Model

To calculate the relationship between stress cycles experienced in pipe and the resulting

fatigue damages, and thus the consumption of fatigue life, relationship of imperial or semi-

empirical nature may be applied. This typically means a determination of the number of

cycles that lead to failure for the various dynamic stress range (e.g. S-N curves) and the

subsequently determination of the accumulation of the partial damages (e.g. Palmer-Miners

law).

9.3 Fatigue Design Criteria

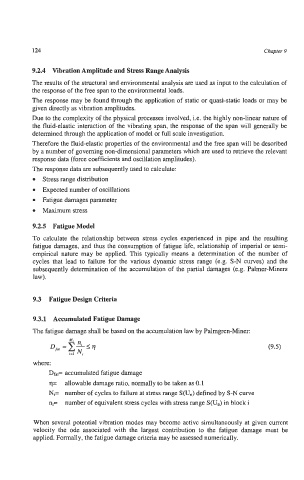

9.3.1 Accumulated Fatigue Damage

The fatigue damage shall be based on the accumulation law by Palmgren-Miner:

where:

DfaF accumulated fatigue damage

q= allowable damage ratio, normally to be taken as 0.1

Ni= number of cycles to failure at stress range S(U.) defined by S-N curve

ni= number of equivalent stress cycles with stress range S(UJ in block i

Whcn sevcral potential vibration modes may bccomc activc simultancousl y at givcn current

velocity the ode associated with the largest contribution to the fatigue damage must be

applied. Formally, the fatigue damage criteria may be assessed numerically.