Page 183 - Pipelines and Risers

P. 183

156 Chapter I I

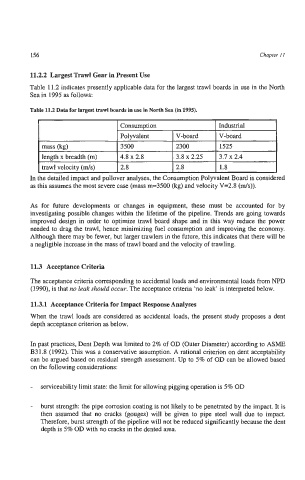

113.2 Largest Trawl Gear in Present Use

Table 11.2 indicates presently applicable data for the largest trawl boards in use in the North

Sea in 1995 as follows:

Consumption Industrial

Polyvalent V-board V-board

mass 0%) 3500 2300 1525

length x breadth (m) 4.8 x 2.8 3.8 x 2.25 3.1 x 2.4

trawl velocity (mls) 2.8 2.8 1.8

L

As for future developments or changes in equipment, these must be accounted for by

investigating possible changes within the lifetime of the pipeline. Trends are going towards

improved design in order to optimize trawl board shape and in this way reduce the power

needed to drag the trawl, hence minimizing fuel consumption and improving the economy.

Although there may be fewer, but larger trawlers in the future, this indicates that there will be

a negligible increase in the mass of trawl board and the velocity of trawling.

11.3 Acceptance Criteria

The acceptance criteria corresponding to accidental loads and environmental loads from NPD

(1990), is that no leak should occur. The acceptance criteria 'no leak' is interpreted below.

113.1 Acceptance Criteria for Impact Response Analyses

When the trawl loads are considered as accidental loads, the present study proposes a dent

depth acceptance criterion as below.

In past practices, Dent Depth was limited to 2% of OD (Outer Diameter) according to ASME

B31.8 (1992). This was a conservative assumption. A rational criterion on dent acceptability

can be argued based on residual strength assessment. Up to 5% of OD can be allowed based

on the following considerations:

- serviceability limit state: the limit for allowing pigging operation is 5% OD

- burst strength: the pipe corrosion coating is not likely to be penetrated by the impact. It is

then assumed that no cracks (gouges) will be given to pipe steel wall due to impact.

Therefore, burst strength of the pipeline will not be reduced significantly because the dent

depth is 5% OD with no cracks in the dented area.