Page 403 - Pipelines and Risers

P. 403

370 Chapter I9

1500

1400

1300

1200

1100

3

;loo0

In

s 900

800

500

60 65

MATERIAL GRADE IKSI)

U O S T PER TONNE (SA/lOOOkql U O S T PER METRE ISAlml

CIA. YJIINLUN WLkY(I NOTE :BASE CASE OF 46 WITH WALL THICKNESS OF 1* FOR MATERILL GRME X65

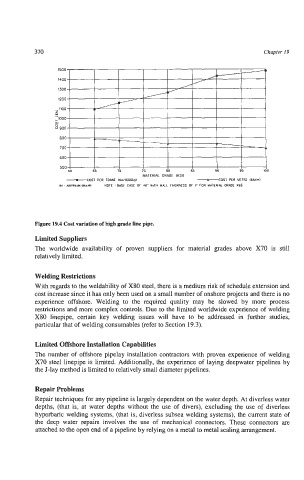

Figure 19.4 Cost variation of high grade line pipe.

Limited Suppliers

The worldwide availability of proven suppliers for material grades above X70 is still

relatively limited.

Welding Restrictions

With regards to the weldability of X80 steel, there is a medium risk of schedule extension and

cost increase since it has only been used on a small number of onshore projects and there is no

experience offshore. Welding to the required quality may be slowed by more process

restrictions and more complex controls. Due to the limited worldwide experience of welding

X80 linepipe, certain key welding issues will have to be addressed in further studies,

particular that of welding consumables (refer to Section 19.3).

Limited Offshore Installation Capabilities

The number of offshore pipelay installation contractors with proven experience of welding

X70 steel linepipe is limited. Additionally, the experience of laying deepwater pipelines by

the J-lay method is limited to relatively small diameter pipelines.

Repair Problems

Repair techniques for any pipeline is largely dependent on the water depth. At diverless water

depths, (that is, at water depths without the use of divers), excluding the use of diverless

hyperbaric welding systems, (that is, diverless subsea welding systems), the current state of

the deep water repairs involves the use of mechanical connectors. These connectors are

attached to the open end of a pipeline by relying on a metal to metal sealing arrangement.