Page 412 - Pipelines and Risers

P. 412

Use offfigh Strength Steel 379

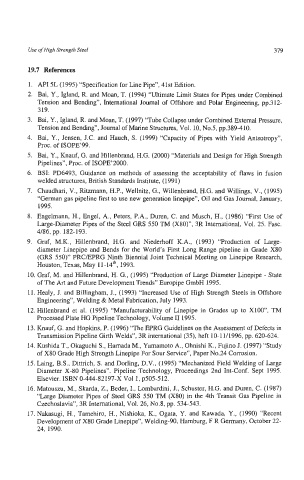

19.7 References

1. API 5L (1995) “Specification for Line Pipe”, 41st Edition.

2. Bai, Y., Igland, R. and Moan, T. (1994) “Ultimate Limit States for Pipes under Combined

Tension and Bending”, International Journal of Offshore and Polar Engineering, pp.312-

319.

3. Bai, Y., Igland, R. and Moan, T. (1997) “Tube Collapse under Combined External Pressure,

Tension and Bending”, Journal of Marine Structures, Vol. 10, NOS, pp.389410.

4. Bai, Y., Jensen, J.C. and Hauch, S. (1999) “Capacity of Pipes with Yield Anisotropy”,

Proc. of ISOPE’99.

5. Bai, Y., Knauf, G. and Hillenbrand, H.G. (2000) “Materials and Design for High Strength

Pipelines”, Proc. of ISOPE’2000.

6. BSI: PD6493, Guidance on methods of assessing the acceptability of flaws in fusion

welded structures, British Standards Institute, (1991)

7. Chaudhari, V., Ritzmann, H.P., Wellnitz, G., Willenbrand, H.G. and Willings, V., (1995)

“German gas pipeline first to use new generation linepipe”, Oil and Gas Journal, January,

1995.

8. Engelmann, H., Engel, A., Peters, P.A., Duren, C. and Musch, H., (1986) “First Use of

Large-Diameter Pipes of the Steel GRS 550 TM (XSO)”, 3R International, Vol. 25. Fasc.

4/86, pp. 182-193.

9. Graf, M.K., Hillenbrand, H.G. and Niederhoff K.A., (1993) “Production of Large-

diameter Linepipe and Bends for the World’s First Long Range pipeline in Grade X80

(GRS 550)” PRCEPRG Ninth Biennial Joint Technical Meeting on Linepipe Research,

Houston, Texas, May 1 1-141h, 1993.

10. Graf, M. and Hillenbrand, H. G., (1995) “Production of Large Diameter Linepipe - State

of The Art and Future Development Trends” Europipe GmbH 1995.

11. Healy, J. and Billingham, J., (1993) “Increased Use of High Strength Steels in Offshore

Engineering”, Welding & Metal Fabrication, July 1993.

12. Hillenbrand et al. (1995) “Manufacturability of Linepipe in Grades up to XlOO”, TM

Processed Plate HG Pipeline Technology, Volume I1 1995.

13. Knauf, G. and Hopkins, P. (1996) “The EPRG Guidelines on the Assessment of Defects in

Transmission Pipeline Girth Welds”, 3R international (35), heft 10-1 14996, pp. 620-624.

14. Kushida T., Okaguchi S., Harnada M., Yamamoto A., Ohnishi K., Fujino J. (1997) “Study

of X80 Grade High Strength Linepipe For Sour Service”, Paper No.24 Corrosion.

15. Laing, B.S., Dittrich, S. and Dorling, D.V., (1995) “Mechanized Field Welding of Large

Diameter X-80 Pipelines”. Pipeline Technology, Proceedings 2nd Int-Conf. Sept 1995.

Elsevier. ISBN 0-444-82197-X Vol 1, p505-512.

16. Matouszu, M., Skarda, Z., Beder, I., Lombardini, J., Schuster, H.G. and Duren, C. (1987)

“Large Diameter Pipes of Steel GRS 550 TM (X80) in the 4th Transit Gas Pipeline in

Czechoslavia”, 3R International, Vol. 26, No.8, pp. 534-543.

17. Nakasugi, H., Tamehiro, H., Nishioka, K., Ogata, Y. and Kawada, Y., (1990) “Recent

Development of X80 Grade Linepipe”, Welding-90, Hamburg, F R Germany, October 22-

24, 1990.