Page 114 - Plant design and economics for chemical engineers

P. 114

9 0 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

extent from the loss of sensible heat to the air. In dry cooling towers, the

temperature reduction of the condenser water depends upon conduction and

convection for the transfer of heat from the water to the air.

Mechanical draft cooling towers either force or induce the air which serves

as the heat-transfer medium through the tower. For their driving force, natural

draft cooling towers depend upon the density difference between the air leaving

the tower and the air entering the tower.

Cooling ponds are generally only considered for heat removal when

suitable land is available at a reasonable price, since such systems are simple,

cheap, and frequently less water-intensive. It is normally assumed that all heat

discharged to a cooling pond is lost through the air-water interface. With low

heat-transfer rates, large surface areas are required.

When land costs are too high, spray ponds often provide a viable alterna-

tive to cooling ponds. It is estimated that a spray pond requires only about 5 to

10 percent of the area of a cooling pond due to the more intimate air-water

contact. In addition, drift losses and corrosion problems are less severe than in

cooling towers.

NOISE CONTROL. The design engineer should include noise studies in the

design stage of any industrial facility. Generally, acoustical problems left for

field resolution cost roughly twice as much. Unnecessary costs incurred in

post-construction noise work may include the replacement of insulation, re-

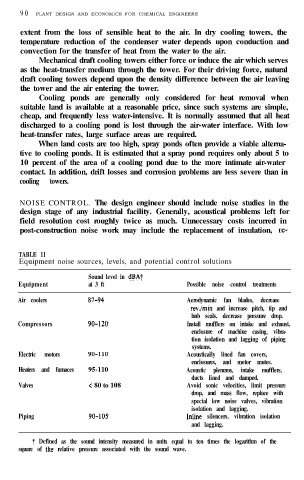

TABLE 11

Equipment noise sources, levels, and potential control solutions

Sound level in dBAf

Equipment at 3 ft Possible noise control treatments

Air coolers 81-94 Aerodynamic fan blades, decrease

rev./min and increase pitch, tip and

hub seals, decrease pressure drop.

Compressors go-120 Install mufflers on intake and exhaust,

enclosure of machine casing, vibra-

tion isolation and lagging of piping

systems.

Electric motors go-110 Acoustically lined fan covers,

enclosures, and motor mutes.

Heaters and furnaces 95-110 Acoustic plenums, intake mufflers,

ducts lined and damped.

Valves < 80 to 108 Avoid sonic velocities, limit pressure

drop, and mass flow, replace with

special low noise valves, vibration

isolation and lagging.

Piping go-105 Inline silencers, vibration isolation

and lagging.

i Defined as the sound intensity measured in units equal to ten times the logarithm of the

square of the relative pressure associated with the sound wave.