Page 104 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 104

80 Polymer-based Nanocomposites for Energy and Environmental Applications

Thermoprobe Tube

PCM sample

Data logger system

Water bath I Water bath II

Software

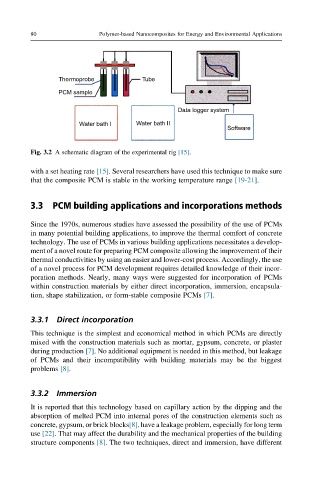

Fig. 3.2 A schematic diagram of the experimental rig [15].

with a set heating rate [15]. Several researchers have used this technique to make sure

that the composite PCM is stable in the working temperature range [19-21].

3.3 PCM building applications and incorporations methods

Since the 1970s, numerous studies have assessed the possibility of the use of PCMs

in many potential building applications, to improve the thermal comfort of concrete

technology. The use of PCMs in various building applications necessitates a develop-

ment of a novel route for preparing PCM composite allowing the improvement of their

thermal conductivities by using an easier and lower-cost process. Accordingly, the use

of a novel process for PCM development requires detailed knowledge of their incor-

poration methods. Nearly, many ways were suggested for incorporation of PCMs

within construction materials by either direct incorporation, immersion, encapsula-

tion, shape stabilization, or form-stable composite PCMs [7].

3.3.1 Direct incorporation

This technique is the simplest and economical method in which PCMs are directly

mixed with the construction materials such as mortar, gypsum, concrete, or plaster

during production [7]. No additional equipment is needed in this method, but leakage

of PCMs and their incompatibility with building materials may be the biggest

problems [8].

3.3.2 Immersion

It is reported that this technology based on capillary action by the dipping and the

absorption of melted PCM into internal pores of the construction elements such as

concrete, gypsum, or brick blocks[8], have a leakage problem, especially for long term

use [22]. That may affect the durability and the mechanical properties of the building

structure components [8]. The two techniques, direct and immersion, have different