Page 119 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 119

Nanoclay and polymer-based nanocomposites: Materials for energy efficiency 95

Si

RO OR

O

RO OR c

Si

Si

g RO OR

a b OR

OR

e RO OR

f Si

d

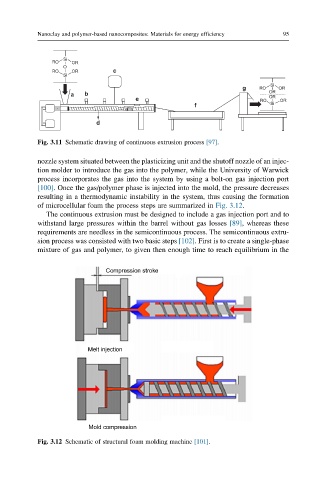

Fig. 3.11 Schematic drawing of continuous extrusion process [97].

nozzle system situated between the plasticizing unit and the shutoff nozzle of an injec-

tion molder to introduce the gas into the polymer, while the University of Warwick

process incorporates the gas into the system by using a bolt-on gas injection port

[100]. Once the gas/polymer phase is injected into the mold, the pressure decreases

resulting in a thermodynamic instability in the system, thus causing the formation

of microcellular foam the process steps are summarized in Fig. 3.12.

The continuous extrusion must be designed to include a gas injection port and to

withstand large pressures within the barrel without gas losses [89], whereas these

requirements are needless in the semicontinuous process. The semicontinuous extru-

sion process was consisted with two basic steps [102]. First is to create a single-phase

mixture of gas and polymer, to given then enough time to reach equilibrium in the

Compression stroke

Melt injection

Mold compression

Fig. 3.12 Schematic of structural foam molding machine [101].