Page 350 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 350

Modification of polymer nanocomposites and significance of ionic liquid 317

H H H H H

CC

H H H H HH n

Ethylene

Polyethylene

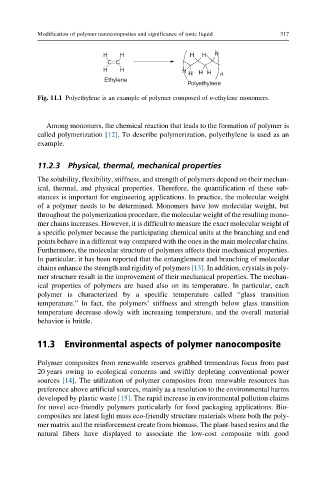

Fig. 11.1 Polyethylene is an example of polymer composed of n-ethylene monomers.

Among monomers, the chemical reaction that leads to the formation of polymer is

called polymerization [12]. To describe polymerization, polyethylene is used as an

example.

11.2.3 Physical, thermal, mechanical properties

The solubility, flexibility, stiffness, and strength of polymers depend on their mechan-

ical, thermal, and physical properties. Therefore, the quantification of these sub-

stances is important for engineering applications. In practice, the molecular weight

of a polymer needs to be determined. Monomers have low molecular weight, but

throughout the polymerization procedure, the molecular weight of the resulting mono-

mer chains increases. However, it is difficult to measure the exact molecular weight of

a specific polymer because the participating chemical units at the branching and end

points behave in a different way compared with the ones in the main molecular chains.

Furthermore, the molecular structure of polymers affects their mechanical properties.

In particular, it has been reported that the entanglement and branching of molecular

chains enhance the strength and rigidity of polymers [13]. In addition, crystals in poly-

mer structure result in the improvement of their mechanical properties. The mechan-

ical properties of polymers are based also on its temperature. In particular, each

polymer is characterized by a specific temperature called “glass transition

temperature.” In fact, the polymers’ stiffness and strength below glass transition

temperature decrease slowly with increasing temperature, and the overall material

behavior is brittle.

11.3 Environmental aspects of polymer nanocomposite

Polymer composites from renewable reserves grabbed tremendous focus from past

20 years owing to ecological concerns and swiftly depleting conventional power

sources [14]. The utilization of polymer composites from renewable resources has

preference above artificial sources, mainly as a resolution to the environmental harms

developed by plastic waste [15]. The rapid increase in environmental pollution claims

for novel eco-friendly polymers particularly for food packaging applications. Bio-

composites are latest light mass eco-friendly structure materials where both the poly-

mer matrix and the reinforcement create from biomass. The plant-based resins and the

natural fibers have displayed to associate the low-cost composite with good