Page 425 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 425

382 Polymer-based Nanocomposites for Energy and Environmental Applications

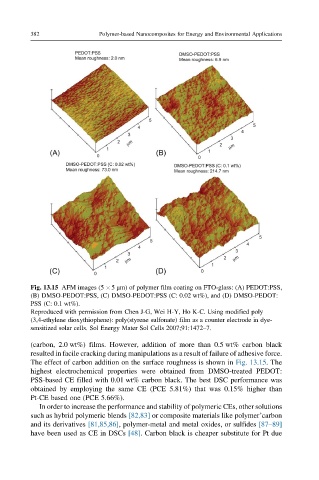

Fig. 13.15 AFM images (5 5 μm) of polymer film coating on FTO-glass: (A) PEDOT:PSS,

(B) DMSO-PEDOT:PSS, (C) DMSO-PEDOT:PSS (C: 0.02 wt%), and (D) DMSO-PEDOT:

PSS (C: 0.1 wt%).

Reproduced with permission from Chen J-G, Wei H-Y, Ho K-C. Using modified poly

(3,4-ethylene dioxythiophene): poly(styrene sulfonate) film as a counter electrode in dye-

sensitized solar cells. Sol Energy Mater Sol Cells 2007;91:1472–7.

(carbon, 2.0 wt%) films. However, addition of more than 0.5 wt% carbon black

resulted in facile cracking during manipulations as a result of failure of adhesive force.

The effect of carbon addition on the surface roughness is shown in Fig. 13.15.The

highest electrochemical properties were obtained from DMSO-treated PEDOT:

PSS-based CE filled with 0.01 wt% carbon black. The best DSC performance was

obtained by employing the same CE (PCE 5.81%) that was 0.15% higher than

Pt-CE based one (PCE 5.66%).

In order to increase the performance and stability of polymeric CEs, other solutions

such as hybrid polymeric blends [82,83] or composite materials like polymer’carbon

and its derivatives [81,85,86], polymer-metal and metal oxides, or sulfides [87–89]

have been used as CE in DSCs [48]. Carbon black is cheaper substitute for Pt due