Page 515 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 515

468 Polymer-based Nanocomposites for Energy and Environmental Applications

+

n + 2.33nFeCl 3 + 0.33Cl – + 2.33nFeCl + 2nHCl

2

*

N N

H H n

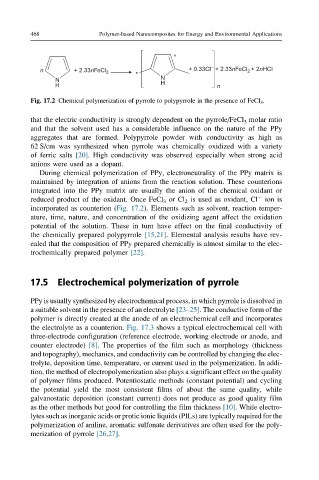

Fig. 17.2 Chemical polymerization of pyrrole to polypyrrole in the presence of FeCl 3 .

that the electric conductivity is strongly dependent on the pyrrole/FeCl 3 molar ratio

and that the solvent used has a considerable influence on the nature of the PPy

aggregates that are formed. Polypyrrole powder with conductivity as high as

62 S/cm was synthesized when pyrrole was chemically oxidized with a variety

of ferric salts [20]. High conductivity was observed especially when strong acid

anions were used as a dopant.

During chemical polymerization of PPy, electroneutrality of the PPy matrix is

maintained by integration of anions from the reaction solution. These counterions

integrated into the PPy matrix are usually the anion of the chemical oxidant or

reduced product of the oxidant. Once FeCl 3 or Cl 2 is used as oxidant, Cl ion is

incorporated as counterion (Fig. 17.2). Elements such as solvent, reaction temper-

ature, time, nature, and concentration of the oxidizing agent affect the oxidation

potential of the solution. These in turn have effect on the final conductivity of

the chemically prepared polypyrrole [15,21]. Elemental analysis results have rev-

ealed that the composition of PPy prepared chemically is almost similar to the elec-

trochemically prepared polymer [22].

17.5 Electrochemical polymerization of pyrrole

PPy is usually synthesized by electrochemical process, in which pyrrole is dissolved in

a suitable solvent in the presence of an electrolyte [23–25]. The conductive form of the

polymer is directly created at the anode of an electrochemical cell and incorporates

the electrolyte as a counterion. Fig. 17.3 shows a typical electrochemical cell with

three-electrode configuration (reference electrode, working electrode or anode, and

counter electrode) [8]. The properties of the film such as morphology (thickness

and topography), mechanics, and conductivity can be controlled by changing the elec-

trolyte, deposition time, temperature, or current used in the polymerization. In addi-

tion, the method of electropolymerization also plays a significant effect on the quality

of polymer films produced. Potentiostatic methods (constant potential) and cycling

the potential yield the most consistent films of about the same quality, while

galvanostatic deposition (constant current) does not produce as good quality film

as the other methods but good for controlling the film thickness [10]. While electro-

lytes such as inorganic acids or protic ionic liquids (PILs) are typically required for the

polymerization of aniline, aromatic sulfonate derivatives are often used for the poly-

merization of pyrrole [26,27].