Page 607 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 607

560 Polymer-based Nanocomposites for Energy and Environmental Applications

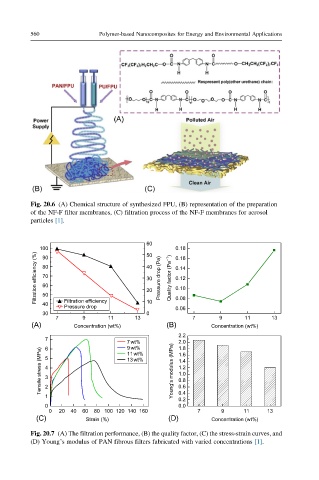

Fig. 20.6 (A) Chemical structure of synthesized FPU, (B) representation of the preparation

of the NF-F filter membranes, (C) filtration process of the NF-F membranes for aerosol

particles [1].

60

100 50 0.18

Filtration efficiency (%) 80 40 Pressure drop (Pa) Quality factor (Pa −1 ) 0.14

90

0.16

70

30

0.12

60

0.10

20

50

Filtration efficiency

40

Pressure drop 10 0.08

0.06

30 0

7 9 11 13 7 9 11 13

(A) Concentration (wt%) (B) Concentration (wt%)

2.2

7

7wt% 2.0

9wt%

1.8

6

Tensile stress (MPa) 5 4 3 13 wt% Young’s modulus (MPa) 1.4

11 wt%

1.6

1.2

1.0

0.8

0.4

1 2 0.6

0.2

0 0.0

0 20 40 60 80 100 120 140 160 7 9 11 13

(C) Strain (%) (D) Concentration (wt%)

Fig. 20.7 (A) The filtration performance, (B) the quality factor, (C) the stress-strain curves, and

(D) Young’s modulus of PAN fibrous filters fabricated with varied concentrations [1].