Page 397 - Power Electronics Handbook

P. 397

386 Power semiconductor circuit applications

Hall generators placed at the commutator switching positions would

therefore react with the rotor field to produce the required position signals.

A further advantage of the Hall detector is that the voltage reverses with

the direction of the magnetic field so that only two sensors at 90"E to each

other need be used for a four-segment commutator.

From three

other

photocells

switches

Photocell

Ii

It

I1

Rotor

Light shield

Light source

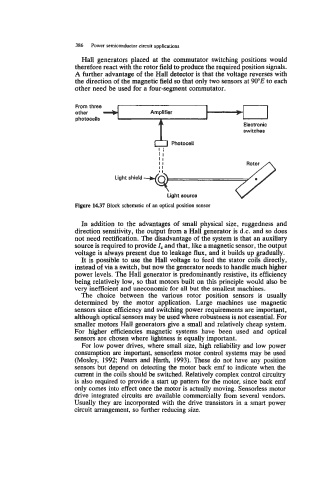

Figure 14.37 Block schematic of an optical position sensor

In addition to the advantages of small physical size, ruggedness and

direction sensitivity, the output from a Hall generator is d.c. and so does

not need rectification. The disadvantage of the system is that an auxiliary

source is required to provide 1, and that, like a magnetic sensor, the output

voltage is always present due to leakage flux, and it builds up gradually.

It is possible to use the Hall voltage to feed the stator coils directly,

instead of via a switch, but now the generator needs to handle much higher

power levels. The Hall generator is predominantly resistive, its efficiency

being relatively low, so that motors built on this principle would also be

very inefficient and uneconomic for all but the smallest machines.

The choice between the various rotor position sensors is usually

determined by the motor application. Large machines use magnetic

sensors since efficiency and switching power requirements are important,

although optical sensors may be used where robustness is not essential. For

smaller motors Hall generators give a small and relatively cheap system.

For higher efficiencies magnetic systems have been used and optical

sensors are chosen where lightness is equally important.

For low power drives, where small size, high reliability and low power

consumption are important, sensorless motor control systems may be used

(Mosley, 1992; Peters and Harth, 1993). These do not have any position

sensors but depend on detecting the motor back emf to indicate when the

current in the coils should be switched. Relatively complex control circuitry

is also required to provide a start up pattern for the motor, since back emf

only comes into effect once the motor is actually moving. Sensorless motor

drive integrated circuits are available commercially from several vendors.

Usually they are incorporated with the drive transistors in a smart power

circuit arrangement, so further reducing size.