Page 402 - Power Electronics Handbook

P. 402

Electrical machine control 391

In general, the electronic commutator motor is best suited to

applications requiring high starting torque, good efficiency at low speeds

and continuous speed variation from standstill to full speed. Due to their

poor efficiency at low speeds, induction motors driven from inverters are

more suited for use in applications where the output is a fixed high speed,

and where, by using crystal-controlled oscillators in the inverter and a

synchronous motor, the speed regulation can be made exceptionally good.

14.3.4 A.C. motors

As outlined in Figure 14.12, there are three basic types of a.c. motors

popularly used with power semiconductor drives, induction, synchronous

and commutator. There is yet another type of motor, the reluctance

machine, which has not been mentioned so far since it can be considered as

a special form of synchronous motor.

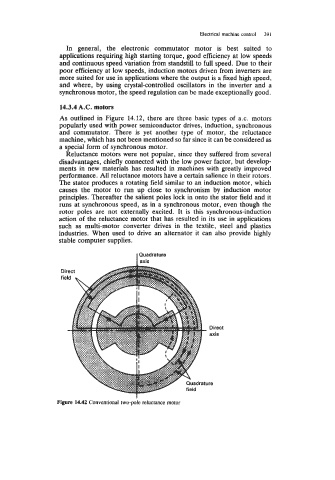

Reluctance motors were not popular, since they suffered from several

disadvantages, chiefly connected with the low power factor, but develop-

ments in new materials has resulted in machines with greatly improved

performance. All reluctance motors have a certain salience in their rotors.

The stator produces a rotating field similar to an induction motor, which

causes the motor to run up close to synchronism by induction motor

principles. Thereafter the salient poles lock in onto the stator field and it

runs at synchronous speed, as in a synchronous motor, even though the

rotor poles are not externally excited. It is this synchronous-induction

action of the reluctance motor that has resulted in its use in applications

such as multi-motor converter drives in the textile, steel and plastics

industries. When used to drive an alternator it can also provide highly

stable computer supplies.

Quadrature

I axis

0

fi

Direct

axis

Quadrati Jre

field

Figure 14.42 Conventional two-pole reluctance motor