Page 408 - Practical Design Ships and Floating Structures

P. 408

383

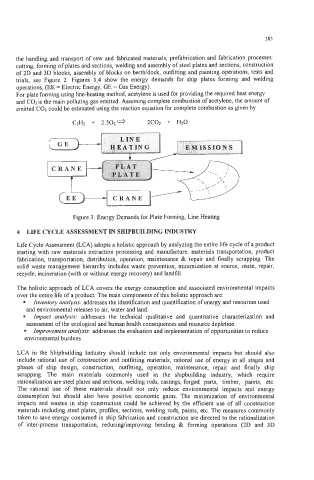

the handling and transport of raw and fabricated materials, prefabrication and fabrication processes:

cutting, forming of plates and sections, welding and assembly of steel plates and sections, construction

of 2D and 3D blocks, assembly of blocks on bertwdock, outfitting and painting operations, tests and

trials, see Figure 2. Figures 3,4 show the energy demands for ship plates forming and welding

operations, (EE = Electric Energy, GE = Gas Energy).

For plate forming using line-heating method, acetylene is used for providing the required heat energy

and COz is the main polluting gas emitted. Assuming complete combustion of acetylene, the amount of

emitted COz could be estimated using the reaction equation for complete combustion as given by:

CzHz + 2.50~~ 2COz + HzO

I

EE CRANE

Figure 3 : Energy Demands for Plate Forming, Line Heating

4 LIFE CYCLE ASSESSMENT IN SHIPBUILDING INDUSTRY

Life Cycle Assessment (LCA) adopts a holistic approach by analyzing the entire life cycle of a product

starting with raw materials extraction processing and manufacture, materials transportation, product

fabrication, transportation, distribution, operation, maintenance & repair and finally scrapping. The

solid waste management hierarchy includes waste prevention, minimization at source, reuse, repair,

recycle, incineration (with or without energy recovery) and landfill.

.

The holistic approach of LCA covers the energy consumption and associated environmental impacts

over the entire life of a product. The main components of this holistic approach are:

Inventory analysis: addresses the identification and quantification of energy and resources used

and environmental releases to air, water and land.

Impact analysis: addresses the technical qualitative and quantitative characterization and

assessment of the ecological and human health consequences and resource depletion.

Improvement analyszs: addresses the evaluation and implementation of opportunities to reduce

environmental burdens

LCA in the Shipbuilding Industry should include not only environmental impacts but should also

include rational use of construction and outfitting materials, rational use of energy in all stages and

phases of ship design, construction, outfitting, operation, maintenance, repair and finally ship

scrapping. The main materials commonly used in the shipbuilding industry, which require

rationalization are steel plates and sections, welding rods, castings, forged parts, timber, paints, etc.

The rational use of these materials should not only reduce environmental impacts and energy

consumption but should also have positive economic gains. The minimization of environmental

impacts and wastes in ship construction could be achieved by the efficient use of all construction

materials including steel plates, profiles, sections, welding rods, paints, etc. The measures commonly

taken to save energy consumed in ship fabrication and construction are directed to the rationalization

of inter-process transportation, reducinglimproving bending & forming operations (2D and 3D