Page 140 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 140

122 Major Process Equipment Maintenance and Repair

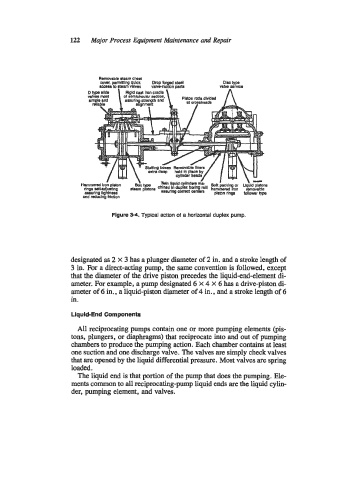

Figure 3-4 Typical action of a horizontal duplex pump.

designated as 2 X 3 has a plunger diameter of 2 in, and a stroke length of

3 in. For a direct-acting pump, the same convention is followed, except

that the diameter of the drive piston precedes the liquid-end-element di-

ameter. For example, a pump designated 6 X 4 X 6 has a drive-piston di-

ameter of 6 in., a liquid-piston diameter of 4 in., and a stroke length of 6

in.

Llquid-End Components

All reciprocating pumps contain one or more pumping elements @is-

tons, plungers, or diaphragms) that reciprocate into and out of pumping

chambers to produce the pumping action. Each chamber contains at least

one suction and one discharge valve. The valves are simply check valves

that are opened by the liquid differential pressure. Most valves are spring

loaded.

The liquid end is that portion of the pump that does the pumping. Ele-

ments common to all reciprocating-pump liquid ends are the liquid cylin-

der, pumping element, and valves.