Page 143 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 143

Reciprocating and Liquid Ring kcuum Pumps 125

9. Packing running dry (pumping chamber gas-bound).

10. Shock conditions arising from entrained gas or cavitation, broken

or faulty valve springs, or system problems.

11. Solids from the pumpage, environment or lubricant.

12. Improper packing installation or break-in (where required).

13. Icing caused by volatile liquids that refrigerate and form ice crys-

tals upon leakage to atmosphere, or by pumping liquids at temper-

atures below 32°F.

As is evident from these conditions, short packing life can indicate

problems elsewhere in the pump or system.

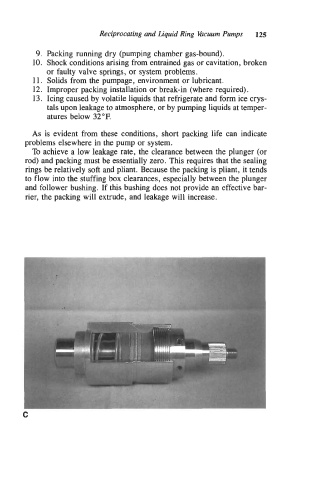

To achieve a low leakage rate, the clearance between the plunger (or

rod) and packing must be essentially zero. This requires that the sealing

rings be relatively soft and pliant. Because the packing is pliant, it tends

to flow into the stuffing box clearances, especially between the plunger

and follower bushing. If this bushing does not provide an effective bar-

rier, the packing will extrude, and leakage will increase.