Page 172 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 172

154 Major Process EquQment Maintenance and Repair

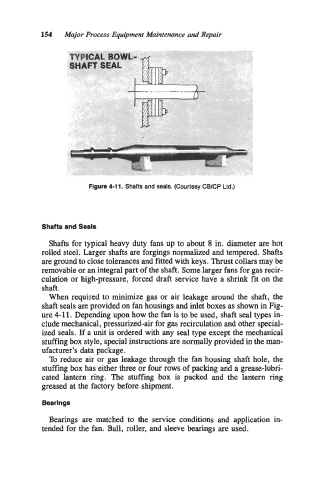

Figure 4-1 1. Shafts and seals. (Courtesy CB/CP Ltd.)

Shafts and Seals

Shafts for typical heavy duty fans up to about 8 in. diameter are hot

rolled steel. Larger shafts are forgings normalized and tempered. Shafts

are ground to close tolerances and fitted with keys. Thrust collars may be

removable or an integral part of the shaft. Some larger fans for gas recir-

culation or high-pressure, forced draft service have a shrink fit on the

shaft.

When required to minimize gas or air leakage around the shaft, the

shaft seals are provided on fan housings and inlet boxes as shown in Fig-

ure 4-1 1. Depending upon how the fan is to be used, shaft seal types in-

clude mechanical, pressurized-air for gas recirculation and other special-

ized seals. If a unit is ordered with any seal type except the mechanical

stuffing box style, special instructions are normally provided in the man-

ufacturer’s data package.

To reduce air or gas leakage through the fan housing shaft hole, the

stuffing box has either three or four rows of packing and a grease-lubri-

cated lantern ring. The stuffing box is packed and the lantern ring

greased at the factory before shipment.

Bearings

Bearings are matched to the service conditions and application in-

tended for the fan. Ball, roller, and sleeve bearings are used.