Page 246 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 246

228 Major Process Equipment Maintenance and Repair

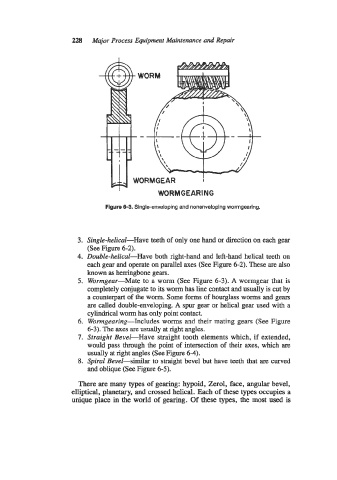

Figure 6-3. Single-enveloping and nonenveloping wormgearing.

3. Single-helical-Have teeth of only one hand or direction on each gear

(See Figure 6-2).

4. Double-helical-Have both right-hand and left-hand helical teeth on

each gear and operate on parallel axes (See Figure 6-2). These are also

known as herringbone gears.

5. Wormgear-Mate to a worm (See Figure 6-3). A wormgear that is

completely conjugate to its worm has line contact and usually is cut by

a counterpart of the worm. Some forms of hourglass worms and gears

are called double-enveloping. A spur gear or helical gear used with a

cylindrical worm has only point contact.

6. Worngearing-Includes worms and their mating gears (See Figure

6-3). The axes are usually at right angles.

7. Straight Bevel-Have straight tooth elements which, if extended,

would pass through the point of intersection of their axes, which are

usually at right angles (See Figure 64).

8. Spiral Bevel-similar to straight bevel but have teeth that are curved

and oblique (See Figure 6-5).

There are many types of gearing: hypoid, Zerol, face, angular bevel,

elliptical, planetary, and crossed helical. Each of these types occupies a

unique place in the world of gearing. Of these types, the most used is