Page 285 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 285

Power Transmission Gears 265

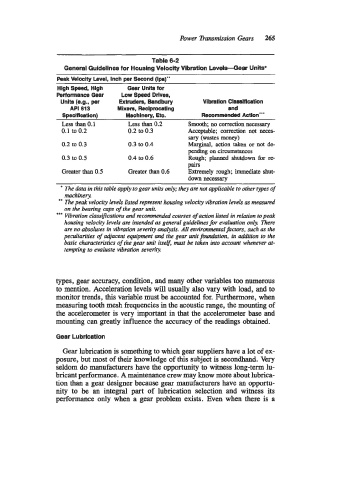

Table 6-2

General Guidelines for Housing Velocity Vibration Levels-Gear Units*

Peak Velocity Level, Inch per Second (Ips)"

High Speed, High Gear Units for

Performance Gear Low Speed Drlves,

Units (e.g., per Extruders, Bandbury Vibratlon Clasaltlcation

API 613 Mixers, Reclprocating and

Speclfication) Machinery, Etc. Recommended Action"'

Less than 0.1 Less than 0.2 Smooth; no correction necessary

0.1 to 0.2 0.2 to 0.3 Acceptable; correction not neces-

sary (wastes money)

0.2 to 0.3 0.3 to 0.4 Marginal, action taken or not de-

pending on circumstances

0.3 to 0.5 0.4 to 0.6 Rough; planned shutdown for re

pail%

Greater than 0.5 Greater than 0.6 Extremely rough; immediate shut-

down necessary

* The data in this table apply to gear units only; they are not applicable to other types of

machinery.

** The peak velocity levels listed represent housing velocity vibration levels as measured

on the bearing caps of the gear unit.

*** Vibration chsificatiom and recommended courses of action listed in relation to peak

housing velocity levels are intended as general guidelines for evaluation only. There

are no absolutes in vibration severity analysis. All environmentalfactors, such as the

peculiarities of adjacent equipment and the gear unit foundation. in addition to the

basic characteristics ofthe gear unit itself. must be taken into account whenever at-

tempting to evaluate vibration severity.

types, gear accuracy, condition, and many other variables too numerous

to mention. Acceleration levels will usually also vary with load, and to

monitor trends, this variable must be accounted for. Furthermore, when

measuring tooth mesh frequencies in the acoustic range, the mounting of

the accelerometer is very important in that the accelerometer base and

mounting can greatly influence the accuracy of the readings obtained.

Gear Lubricatlon

Gear lubrication is something to which gear suppliers have a lot of ex-

posure, but most of their knowledge of this subject is secondhand. Very

seldom do manufacturers have the opportunity to witness long-term lu-

bricant performance. A maintenance crew may know more about lubrica-

tion than a gear designer because gear manufacturers have an opportu-

nity to be an integral part of lubrication selection and witness its

performance only when a gear problem exists. Even when there is a