Page 288 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 288

268 Major Process Equipment Maintenance and Repair

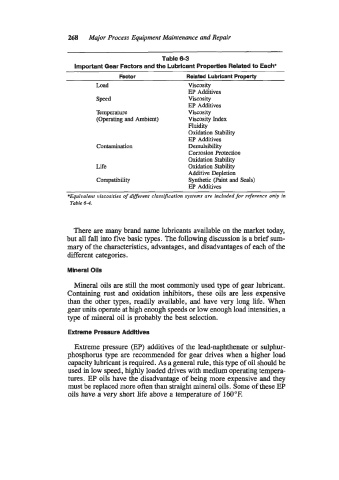

Table 6-3

Important Gear Factors and the Lubricant Properties Related to Each*

Factor Related Lubricant Prow*

Load Viscosity

EP Additives

Speed Viscosity

EP Additives

Temperature Viscosity

(Operating and Ambient) Viscosity Index

Fluidity

Oxidation Stability

EP Additives

Contamination Demulsibility

Corrosion Protection

Oxidation Stability

Life Oxidation Stability

Additive Depletion

Compatibility Synthetic (Paint and Seals)

EP Additives

*Equivalent viscosities of different classification systems are included for reference only in

Table 6-4.

There are many brand name lubricants available on the market today,

but all fall into five basic types. The following discussion is a brief sum-

mary of the characteristics, advantages, and disadvantages of each of the

different categories.

Mineral Oils

Mineral oils are still the most commonly used type of gear lubricant.

Containing rust and oxidation inhibitors, these oils are less expensive

than the other types, readily available, and have very long life. When

gear units operate at high enough speeds or low enough load intensities, a

type of mineral oil is probably the best selection.

Extreme Pressure Addltlves

Extreme pressure (EP) additives of the lead-naphthenate or sulphur-

phosphorus type are recommended for gear drives when a higher load

capacity lubricant is required. As a general rule, this type of oil should be

used in low speed, highly loaded drives with medium operating tempera-

tures. EP oils have the disadvantage of being more expensive and they

must be replaced more often than straight mineral oils. Some of these EP

oils have a very short life above a temperature of 160°F.