Page 294 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 294

274 Major Process Equipment Maintenance and Repair

viscosity preferable for compressor seals or bearings is selected, and

gear life is probably reduced. The bearings in a gear unit can use the

lightest oils available, but gear teeth need a much heavier, more viscous

oil to increase the film thickness between the teeth.

When lighter viscosity oils (such as light turbine oil which has a viscosity

of 150 SSU at 100°F) are necessary, inlet oil temperatures should be limited

to 110 to 120°F to maintain an acceptable viscosity. In addition, the oil

should be supplied in the temperature and pressure range specified by the

manufacturer. See Table 6-4.

In high speed gears with a pitch line speed of up to approximately

15,000 ft per minute, the oil should be sprayed into the out-mesh. This

procedure allows maximum cooling time for the gear blanks and applies

the oil at the highest temperature area of the gears. Furthermore, a nega-

tive pressure is formed when the teeth come out of mesh, and this pres-

sure pulls the oil into the tooth spaces.

Above approximately 15,000 ft per minute, 90 percent of the oil

should be sprayed into the out-mesh and 10 percent into the in-mesh.

This additional spraying of the in-mesh is a safety precaution to assure

the amount of oil required for lubrication is available at the mesh. In ad-

dition, for gears in the speed ranges from 25,000 to 40,000 ft per minute

pitch line velocity, oil should be sprayed on the sides and in the gap area

(on double helical types) of the gears to minimize thermal distortion.

The primary detrimental effect of inadequate lubrication is scoring or

scuffing (adhesive wear) which is caused when the oil film does not pre-

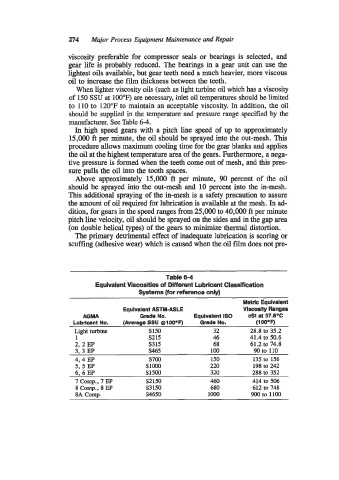

Table 6-4

Equivalent Viscosities of Different Lubricant Classification

Systems (for reference only)

Metric Equivalent

Equlvalent ASTM-ASLE Vlscodty Ranges

AGMA Grade No. Equivalent IS0 cSt a1 37.8OC

Lubricant No. (Average SSU @lOO°F) Grade No. (100OF)

Light turbine S150 32 28.8 to 35.2

1 S215 46 41.4 to 50.6

2,2 EP S315 68 61.2 to 74.8

3,3 EP S465 100 90 to 110

4,4 EP s700 150 135 to 156

5,5 EP Slo00 220 198 to 242

6.6 EP S1500 320 288 to 352

7 Cornp., 7 EP S2 150 460 414 to 506

8 Comp., 8 EP S3150 680 612 to 748

8A Comp. S4650 lo00 900 to 1100