Page 365 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 365

344 Major Process Equipment Maintenance and Repair

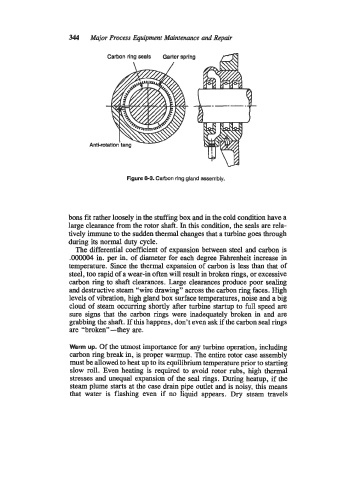

Carbon ring seals Garter spring

-----

Figure 8-3. Carbon rlng gland assembly.

bons fit rather loosely in the stuffig box and in the cold condition have a

large clearance from the rotor shaft. In this condition, the seals are rela-

tively immune to the sudden thermal changes that a turbine goes through

during its normal duty cycle.

The differential coefficient of expansion between steel and carbon is

.OOOOO4 in. per in. of diameter for each degree Fahrenheit increase in

temperature. Since the thermal expansion of carbon is less than that of

steel, too rapid of a wear-in often will result in broken rings, or excessive

carbon ring to shaft clearances. Large clearances produce poor sealing

and destructive steam “wire drawing” across the carbon ring faces. High

levels of vibration, high gland box surface temperatures, noise and a big

cloud of steam occurring shortly after turbine startup to full speed are

sure signs that the carbon rings were inadequately broken in and are

grabbing the shaft. If this happens, don’t even ask if the carbon seal rings

are “broken”-they are.

Warm up. Of the utmost importance for any turbine operation, including

carbon ring break in, is proper warmup. The entire rotor case assembly

must be allowed to heat up to its equilibrium temperature prior to starting

slow roll. Even heating is required to avoid rotor rubs, high thermal

stresses and unequal expansion of the seal rings. During heatup, if the

steam plume starts at the case drain pipe outlet and is noisy, this means

that water is flashing even if no liquid appears. Dry steam travels