Page 73 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 73

58 Practical Machinery Management for Process Plants

1

Oil

---

level

I

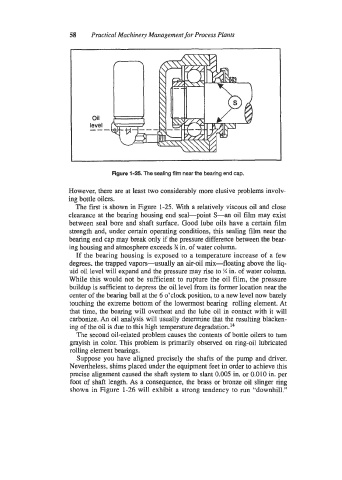

Figure 1-25. The sealing film near the bearing end cap.

However, there are at least two considerably more elusive problems involv-

ing bottle oilers.

The first is shown in Figure 1-25. With a relatively viscous oil and close

clearance at the bearing housing end seal-point S-an oil film may exist

between seal bore and shaft surface. Good lube oils have a certain film

strength and, under certain operating conditions, this sealing film near the

bearing end cap may break only if the pressure difference between the bear-

ing housing and atmosphere exceeds % in. of water column.

If the bearing housing is exposed to a temperature increase of a few

degrees, the trapped vapors--usually an air-oil mix-floating above the liq-

uid oil level will expand and the pressure may rise to !4 in. of water column.

While this would not be sufficient to rupture the oil film, the pressure

buildup is sufficient to depress the oil level from its former location near the

center of the bearing ball at the 6 o'clock position, to a new level now barely

touching the extreme bottom of the lowermost bearing rolling element. At

that time, the bearing will overheat and the lube oil in contact with it will

carbonize. An oil analysis will usually determine that the resulting blacken-

ing of the oil is due to this high temperature degradation.14

The second oil-related problem causes the contents of bottle oilers to turn

grayish in color. This problem is primarily observed on ring-oil lubricated

rolling element bearings.

Suppose you have aligned precisely the shafts of the pump and driver.

Nevertheless, shims placed under the equipment feet in order to achieve this

precise alignment caused the shaft system to slant 0.005 in. or 0.010 in. per

foot of shaft length. As a consequence, the brass or bronze oil slinger ring

shown in Figure 1-26 will exhibit a strong tendency to run "downhill."