Page 74 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 74

Installation, Maintenance. and Repair of Horizontal Pimps 59

I

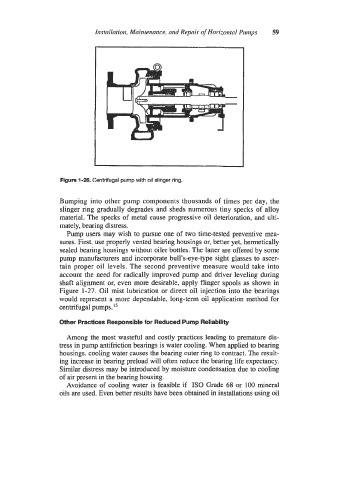

Figure 1-20. Centrifugal pump with oil slinger ring.

Bumping into other pump components thousands of times per day, the

slinger ring gradually degrades and sheds numerous tiny specks of alloy

material. The specks of metal cause progressive oil deterioration, and ulti-

mately, bearing distress.

Pump users may wish to pursue one of two time-tested preventive mea-

sures. First, use properly vented bearing housings or, better yet, hermetically

sealed bearing housings without oiler bottles. The latter are offered by some

pump manufacturers and incorporate bull’s-eye-type sight giasses to ascer-

tain proper oil levels. The second preventive measure would take into

account the need for radically improved pump and driver leveling during

shaft alignment or. even more desirable. apply flinger spools as shown in

Figure 1-27. Oil mist lubrication or direct oil injection into the bearings

would represent a more dependable, long-term oil application method for

centrifugal pumps.

Other Practices Responsible for Reduced Pump Reliability

Among the most wasteful and costly practices leading to premature dis-

tress in pump antifriction bearings is water cooling. When applied to bearing

housings, cooling water causes the bearing outer ring to contract. The result-

ing increase in bearing preload will often reduce the bearing life expectancy.

Similar distress may be introduced by moisture condensation due to cooling

of air present in the bearing housing.

Avoidance of cooling water is feasible if IS0 Grade 68 or 100 mineral

oils are used. Even better results have been obtained in installations using oil