Page 17 - Pressure Vessel Design Manual

P. 17

4 Pressure Vessel Design Manual

,- Failure surface (yield surface boundary)

P

t O1

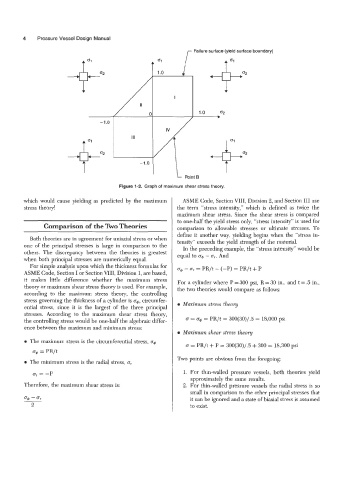

Figure 1-2. Graph of maximum shear stress theory.

which would cause yielding as predcted by the maximum ASME Code, Section VIII, Division 2, and Section I11 use

stress theory! the term “stress intensity,” which is defined as twice the

maximum shear stress. Since the shear stress is compared

to one-half the yield stress only, “stress intensity” is used for

Comparison of the Two Theories comparison to allowable stresses or ultimate stresses. To

define it another way, yieldmg begins when the “stress in-

Both theories are in agreement for uniaxial stress or when tensity” exceeds the yield strength of the material.

one of the principal stresses is large in comparison to the In the preceding example, the “stress intensity” would be

others. The discrepancy between the theories is greatest equal to 04 - a,. And

when both principal stresses are numerically equal.

For simple analysis upon which the thickness formulas for

ASME Code, Section I or Section VIII, Division 1, are based,

it makes little difference whether the maximum stress For a cylinder where P = 300 psi, R = 30 in., and t = .5 in.,

theory or maximum shear stress theory is used. For example, the two theories would compare as follows:

according to the maximum stress theory, the controlling

stress governing the thickness of a cylinder is 04, circumfer- Maximum stress theory

ential stress, since it is the largest of the three principal

stresses. Accordmg to the maximum shear stress theory,

the controlling stress would be one-half the algebraic differ- o = a4 = PR/t = 300(30)/.5 = 18,000 psi

ence between the maximum and minimum stress:

Maximum shear stress the0 y

The maximum stress is the circumferential stress, a4

a = PR/t + P = 300(30)/.5 + 300 = 18,300 psi

04 = PR/t

Two points are obvious from the foregoing:

0 The minimum stress is the radial stress, a,

a, = -P 1. For thin-walled pressure vessels, both theories yield

approximately the same results.

Therefore, the maximum shear stress is: 2. For thin-walled pressure vessels the radial stress is so

small in comparison to the other principal stresses that

it can be ignored and a state of biaxial stress is assumed

to exist.