Page 223 - Pressure Vessel Design Manual

P. 223

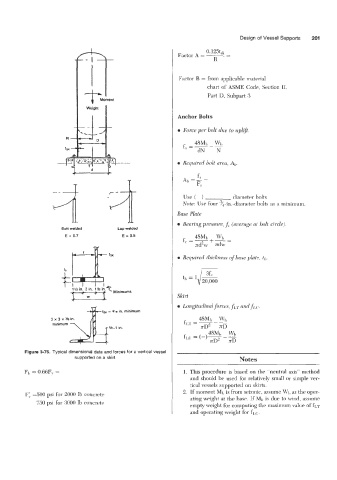

Design of Vessel Supports 201

0.125tSk

-

Factor A = ___ -

R

Factor B = from applicable material

chart of ASME Code, Section 11.

Part D, Subpart 3

Anchor Bolts

0 Force per bolt due to uplij?

48Mb wb

f

’- dN N

0 Required bolt urea, AI,.

4 :d Base Plate diameter bolts

Use ( )

Note: Use four ‘?$-in.-diameter bolts as a minimum.

Butt

welded

+--

E = 0.7 Lap welded Bearing pressure, fc (uveruge at bolt circle).

E = 0.5

48M1, WI, -

f, = 2

na ndw

0 Required thickness of base plate, tl,.

tt, = I/- 3f,

20,000

Skirt

e Longitudinal force.s, fL,T and fL(..

in.

=

tsK = %e in. minimum

minimum

tsK

%e

3 x 3 x %in.

3

%in.

x

3

x

minimum

minimum

1h-1

1h-1 in.

in.

Figure 3-76. Typical dimensional data and forces for a vertical vessel

supported on a skirt. Notes

FI, = 0.66FV = 1. This procedure is based on the “neutral axis” method

and should he used for relatively small or simple ver-

tical vessels supported on skirts

2. If moment M1, is from seismic, assume Wi) as the oper-

F: =SO0 psi for 2000 lb concrete

ating weight at the base. If MI, is due to wind, assume

$50 psi for 3000 lb concrete empty weight for computing the maxinlrim value of frAT

and operating weight for fL(:.