Page 30 - Pressure Swing Adsorption

P. 30

:1 i

4 PRESSURE SWING ADSORPTION INTRODUCTION 5

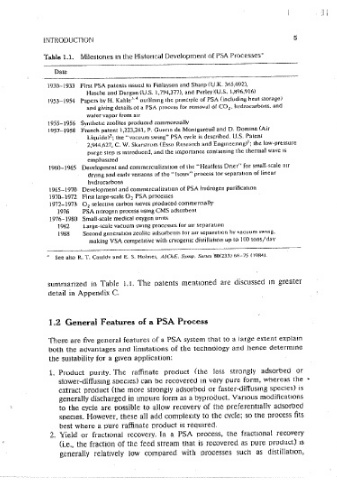

As a result, both lhe conceptual framework and the design procedures are Table 1.1. Milestones m the Historical Development of PSA Processes~

ouite different. This difference can best be explained in rnath~mat 1 cal terms.

Date

A steady-state process can be described mathemat1cally by an ordinary

differential eouat10n (or a set of ordinary differential equations), and to 1930-1933 First PSA patents issued to Finlayson and Sharp <U.K. 365,092).

obtain the relationship between the operating variables and the process Hasche and Dargan (U.S. 1,794,377), and Perlev:(U.S. 1,896,916)

1 4

performance requires only the integration of this set of equat10ns. By 1953-1954 Papers bv H. Kah!e· • outlining the principle of PSA (including heat storage;

and giving detall!. ot a PSA process for removal of CO 2 , hydrocarbons. and

contrast, a transient process 1s described by a set of partial differential

water vapor from air

eauations and this requires a more complex solution procedure. As a result 1955-1956 Svnthettc zeolites produced commerc1allv

the relat10nship between the process performance and the operational van- 1957-1958 F-rench patent 1,223,261, P. Ouerm de Monlgareuii and D. Domine (Air

2

ables 1s generally less obvious. Procedures for the design and scaleup or PSA Uquidel : the "vacuum swing" PSA cvcle is described. U.S. Patem

1

2,944,627,· C. W. Skarstrnm (Esso Research and Engmeenng) ; the !ow-pressure

units are for tile most oart available m the open iiterature. However, they

purge step 1 s mrroduced, and the importance contammg the 1hermal wave 1s

have not yet been generally accepted as oart of the normal chemical eng1-

emphasized

neenng curriculum and, as a resuit, a certam air of mvstery persists.

1960-1965 Development and commerc1alizat1on ol the "Heat less Oner" for small-scale atr

Despite their eariy mceptlon, 1t was really only dnrmg the 1980s that PSA drvmg and ear!v versions of the "lsos1v'' process tor separation of linear

processes gamed widespread commercial acceptance. This 1s illustrated m hvdrocarbons

Figure 1.2, which shows a plot of the annual numbers of publications and 1965-1970 Development and commerc1aliza11on of PSA hvdrogen purificat1or1

U.S. patents relatmg to PSA processes against the year. The reasons for this 1970-1972 First large-scale 0 2 PSA processes

1972-1973 0 selecuve carbon sieves produced commercially

unusually long deiay between the mventton and commercializat1on of such 2

1976 PSA mtrogen process usmg CMS adsorbent

orocesses are not entirelv clear, but 1t seems likely that the opposition of 1976-1980 Small-scale medical oxygen un11s

entrenched interests m the cryogemc gas mdustry and the iack of familiarity 1982 Large-seal<! vacuum swmg proc..:sses for a\f separation

with the underlying onnc1ples among practicing engineers were probably 1988 Second generation zeolite adsorbent.~ tor air separai1on hv vacuum swmg,

making VSA competllive with crvoge111c dis1illat1on up to JOO 1ons/dav

significant factors. Dunng the 1970s mterest m alternative separation pro-

cesses was sumulate(t by the escalation of energy costs associated with See also R. T. Cassidv and E- S. Holmes, AJChE. Swnp. Senes ·s0(233J 68-75 ( 1984).

the nsmg pnce of crude oil. Although energy costs fell dnring the 1980s, the

impetus to examine alternative processes and to match the technoiogy to the

product specifications has continued. summarized in Tabk LI. The patents mentioned are discussed m greater

detail in Appendix C.

1.1 Historical Development of PSA Processes

1.2 General Features of a PSA Process

The introduction of PSA processes 1s commonly attributed to Skarstrorn 1 and

Guerin de Montgareuil and Domme 2 m 1957-1958. However, manv of the There are five general features of a PSA system that to a large extent explain

essential features of this type of process were delineated much earlier m the both the advantages and limitations of the technOJogy and hence determme

3 4

papers of Kahle • and in the oioneering patents of Hasche and Dargan, 5 the suitability for a given application:

7

Perley.' and Finlayson and Sharp, * which were filed between 1927 and 1930

hut have been largeiy overlooked by more recent authors. The Air LiQuide 1. Product punty. The raffinate product (the less strongly adsorbed or

process, developed by Guerm de Montgareuil and Domme, utilized a va~uum slower-diffusmg species) can be recovered m very pure form, whereas th_e

swing, whereas the Esso process, oioneered by Skarstrotn, used a low-pres- extract product (the more strongly adsorbed or faster-diffusmg species) 1s

sure purge to clean the adsorbent bed followmg the blowdown steo. Details generally discharged in impure form as a byproliuct. Vanous modifications

of both cycles, which are still m common use, are given in Chapter 3. Some to the cycle are possible to allow recovery of the oreferent1allv adsorb~d

other key dates m the chronological development of PSA technology are species. However, these all add comolexrty to the cvcle: so the process fits

best where a pure raffinate product is required.

2. Yield or fractional recoverv. In a PSA process, tt1e fractwnal recovery

* The authors are grateful to Dr. Norman Kirkby of the Umversitv of Surrey for pomtmg om (i.e., the fraction of the feed stream that is recovered as pure product) ,s

this reference. generally relatrveiy low compared with processes such as distillat1on,