Page 32 - Pressure Swing Adsorption

P. 32

1'"'

6

PRESSURE SWING ADSORPTION INTRODUCTION 7

ahs<_u-ptinn. or extracuon. The recovery can he mcrcascd by mcluding

However, if the feed 1~ already available ar high :nres~urc. these CCJ'-i!'-, mav

addn1onal steps 111 the cvcle anll by incrc.is1ng the number of adsorbent

be greatly reduced, since not i'mly are the capital cos,~ and power

beds, bu_t both these modifications increase the earntal cost. A PSA

requtrement reduced, but the cost of product recornpress1on will generallv

oro~ess therefore fits best when the feed is relatively cheap so that a high be much lower than the cost of compressing the feed to the higher

Product yield is not a matter of pnmary concern.

operatmg pressure. A PSA system 1s therefore esoec1allv usefui where the

3. Co~centration of trace 1mounties. Where a highly selective adsorbent s

1 feed 1s available at elevated pressure.

available a PSA process can provide a valuable means of concentrating

5. Scaling characteristics. The operating costs of mo:-.t separat10n processes

irncc unourities, but this applicat1on has not yet been <.1evcioped it) any

significant extent. increase approximately linearly wJth throughput. ·The capit.i! cost of a PSA

process ts also approximately linear with throughput, hur for most other

4. Energy reoutrements. Like most seoarat1on processes, the energy effi-

processes the caonal cost curve 1s highly nonlinear, with the incremental

ciency of a PSA Process 1s relatively low. The First Law efficiency (sep-

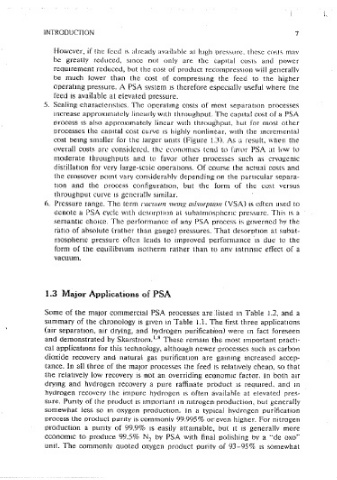

cost bemg smaller for the larger units (Figure 1..3). As ,, resuit. when the

aration work rciat1ve to energy consumed) 1s 111 fact comparable wilh that

overall costs arL· CLHlsidercd. tt1c C-L'l)1wm1cs tend lt) fa\"lW PSA at ll1 W io

of processes such as distillation or extraction, but a PSA system uses

moderate throughputs and to favor other processes such as crvogernc

mechamcal energy, which is in general more expensive than heat. The

distillation for very large-scaic ooerat1ons. Of course the actual costs and

power cost 1s the maJor comronent of the opcraimg cost for a PSA system.

the crossover nomt vary considerahlv depending on the parucuiar scpara-

tJOn and the process configuration, but the form of the cost versus

throughput curve ,s genera!lv s1miiar.

PSA / / 6. Pressure range. The term t·ac111m1 ,;wmg admrpuon (VSA) 1s often used to

/

Total Proce-ss _,,... _,,... Distillation etc.

Costs 1/ denote a PSA cvclc with Llcsorpiron at suhmmosphcnc 11rc::-.surc. This 1s a

semantic choice. The performance of any PSA process is governed bv the

/t ratw of absolute (rather than gauge) pressures. That desorption at subat-

// I mosohenc pressure often leads to improved performance -1s due to the

/ Cross01Jer form of the equilibnum isotherm rather than to anv mtnns1c effect of a

/ Pomt vacuum.

I

I

I

PSA

Operating Cost 1.3 Major Applications of PSA

( Power) /

/

/

;;; .,,,,- "'oistillation etc. Some of the maJor commercial PSA processes are :listed m Table 1.2, and a

0 summary of the chronology 1s given m Table l. 1. The first three applications

u / /

/ (air separation, air drying, and hydrogen ourificatibn) were m fact foreseen

/

/ 11

/ and demonstrated by Skarstrom.1. These remam the most important oract1-

1/

cat applications for this technology, although newer processes such as carbon

PSA

-- tance. In all three of the maJor processes the feed 1s relatively cheap, so that

Capital Cost --- dioxide recovery and natural gas purification are gammg 111creased accep-

_,,,,,,,,...--- -Distillation etc. the relatively low recovery is not an overriding ecQnom1c factor. In both air

drymg and hydrogen recovery a pure raffi.nate product 1s rec1mred. and m

/

/ hydrogen recovery the impure hydrogen 1s often avai\ah!c at elevated pres-

I

I sure. Punty of the product 1s 1mporian1 m nitrogen production, hut generally

somewhat Jess so m oxygen production. Jn a typical hvdrngen purification

process the oroduct ounty is commonly 99.995% or even higher. For nitrogen

Throughput-

oroduction a purity of 99.9% 1s easily attainable, but 1t is generallv more

Figure 1.3 Variation of cost with throughpui for PSA and cryogenic mr scparatmn economic to produce 99.5% N by PSA with final polishing lJY a .. de oxo"

processes: 2

unit. The commonly quoted oxygen product purity of 93-95% 1s somewhat