Page 94 - Pressure Swing Adsorption

P. 94

68 PRESS II RE SWING ADSORPTION

PSA CYCLES: BA51C PRINCIPLES 69

Table 3.1. Summary of the Elementary Steps Used in PSA Cycles

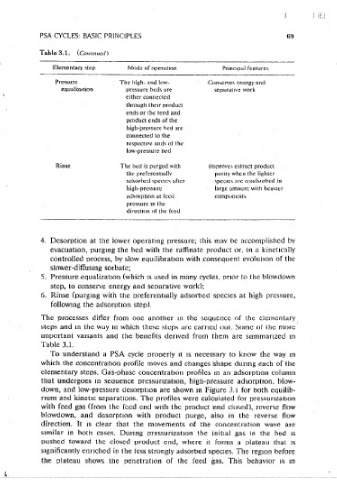

Table 3.1. (Conmwed)

Elemenrnry step Mo<le ot operatmn Principal features Elementary steri Mock of orierat1on Princira! feature~

Pressunzat1on i. Press11nzu11on with Enrichment or the less Pressure The high- and low- Comerves energy ;lnd

fee<l from the foed selectively adsorbed egu&lization pres,,ure bc<ls are separative work

end species m the gas phase

either connected

at the product end

through their product

2. Pressurization with Sharpens the concentration

ends or the teed and

raffinate product from front, which improves the

product ends of the

the product end pnor purity and recoverv of

high-pressure hed are

to feed pressunzat1on raffinate product connected lo the

respecuve ends ot the

High-pressure 1. Product (raffinate) Raffinate produc1 1s

low-pressure bed

adsorption withdrawal at constant delivered at high pressure

coiumn pressure Rinse The bed is purged with i'mprove~ extract product

2. The column r,ressure ·1s Verv high recovery of the the preferentrnllv purny when !he liRhler

;1llowed to decrease less sciectivliv adrnrhed

atl.'>orhcd specie., ;1ftcr spcoc~ <m.: coachorhed in

while the rullinuie species rnav be achieved.

high-pressurt: large .imount with heavier

product 1s drawn from hut lhc product 1s adsorption at fccU components

the product end delivered at low pressure

pressure m I he

direc:tmn of the feed

Blowdown I. Countercurrent Usetl when onlv raltinaie

blowdown to a low product 1s reomred at high

pressure punty; prevents contammat1on

of the product end with more 4. Desorption at the iower operating pressure; this mav be accomplished by

strongly adsorbed species

evacuation, purgmg the bed with the rnffinate product or, m a kinetically

2. Cocurrent blowdown Used when extract product

to an mtermediate ,s also reamred in high controlled process, by slow equilibration with consequent evoluuon of the

pressure pnor to punty; improves exlract slower-diffusing sorbate;

countercurrent product purltV and mav also 5. Pressure equalization (which JS used in many cycles. pnor to the blowdown

blowdown mcrease raffinate recovery step, to conserve energy and seoarative work);

6. Rinse (purging with the oreferentially adsorbect-soecies at high pressure,

Desorption I. Couniercurre111 Improves raffinate product

at low desorption with at the expense ot decrease following the adsorotmn step).

pressure product purge m recover,,: purge at The processes differ from one another 111 the sequence of the elementary,

subatmmphcnc pressure

steps and m the way in which these steps arc earned ouL Some of the mon;

reduces raflinate product

loss bm increases energy important vanants and the benefits derived from them are summarized 10

COSI Table 3.1.

2. Countercurreni Recovery enhancement while

To understand a PSA cycle properly It 1s necessary to know the way m

desorption without mamrnmmg high product

external purge purity 1s possible oniy m which the concentration profile moves and changes 'shape during each of the

elementary steos. Gas-phase concentratrnn profiles m an adsorotion column

certain kinetic separation

3. Evacuation High punty of both that undergoes m sequence oressunzatton, high-ptessure adsorot1on. blow-

extract and raffinate down, and low-pressure desorption are shown m Figure 3. i for both equilib-

products; advantageous over rium and kinetic separations. The profiles were calculated for pressurization

producl purge when the

allsorbei.l phase 1s very with feed gas (from the feed end with the product 'end closed), reverse flow

strongly hdd biowdown, and desorption with product purge, aiso in the reverse flow

direction. It 1s clear that the movements of the concentration wave are

(Cml!mued)

similar in both cases. During pressurization the initial gas in the hed 1s

pushed toward the closed product end, where it forms a plateau that 1s

significantly enriched in the less strongiy adsorbed species. The region before

the plateau shows the penetration of the feed gas. This behavior 1s m