Page 98 - Pressure Swing Adsorption

P. 98

!Ii

72 PRESSURE SWING ADSORPTION PSA CYCLES: BASIC PRINCIPLES 73

in such a process the ouriiy of the ratfinate product and the extent of

RAFFINATE PRODUCT

adsorbent regeneration depend on the partial pressure of the strongly ad-

sorhed $pecies m the void volume of the column at the end of the desorption

Sll'p. In that step the desorhing gas, which 1s nch in strongly adsorbed

species, occupies the void volume of the column, and, unless adequately

removed from the bed, this gas will contaminate the raffinale product. The

early PSA cycles were based on two different techniques for regenerating the

adsorbent and cleanmg the void volume. The cycle develooed by Skarstrorn 2

(see the following) cmpioycd atmospheric dcsorntion with product purge,

while the Air Liouide cycle:: utilized vacuum desorot1on. Evacuation to a very

low absolute pressure may be necessary to achieve reasonable regeneration

bv vacuum desorption, especially when the isotherm for the more strongly

adsorbed component 1s of favorable (type I) form. However, vacuum desorp-

tion has other advantages (such as reduction m the power reamrement) ano

is still widely used, particulariy for kinetic separations.

3.2.1 The Skarstrom Cycle

2 4

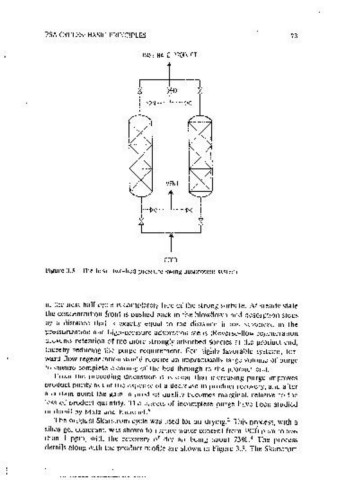

The Skarstrom cycle • m 1ts basic form utilizes two packed adsorbent beds,

as shown schematically m Figure .3.3. The following four Mcps comprise the

cvdc:

l. Pressunzat1on;

2. Adsorption;

3. Countercurrent blowdown; and FEED

4. Countercurrcnt purge. Figure 3,3 The basic two-bed pressure swing adsororton svstcm.

Both beds undergo these four operations and the sequence, shown m Figure

3.4, 1s phased in such a way that a continuous flow of product 1s mamtamed.

In step 1, bed 2 is oressunzed to the higher operating pressure, with feed m the next half-cycle ts cornoleteiy free of the strong sorbate. At steactv state

from the feed end, while bed 1 JS blown down to the atmosohenc pressure m the concentration front 1s oushed back m the blowdown and desorption steps

Ille opposite direction. In step 2, high-pressure feed flows through bed 2. The by a distance that is exactly equal to the distance it has advanced 111 the

more strongly adsorbed component 1s retained in the bed and a gas stream pressunzation and high-pressure adsorotion steps. :Reverse-flow regeneration

enriched m the less strongly adsorbed component leaves as effluent at a prevents retention of the more strongly adsorbed Species at the product end,

pressure only slightly below that of the feed. A fraction of the effluent stream thereby reducmg the purge requirement. For highly favorable systems, for-

1s withdrawn as product and the rest 1s used to purge bed I at the low ward-flow regenerarmn would reQUire an 1mpract1dallv iarge volume of purge

operating pressure. The direction of the purge flow 1s aiso opposite to that of

to ensure compiete cleaning of the bed through to the product end.

the fccJ flow. Steps 3 and 4 follow the same sequence but with the beds From the preceding discussion Ji ,~ dear that increasing purge improves

mtcrchangc<l.

product punty hm at the expense of a decrease 111 product recovery, <ind after

Durmg the high-pressure adsorption step the gas ohase behind the front a certain ooint the gam m product quality becomes marginal, relative to the

has essentially the feed composition, whiie the composition beyond the front

loss of product a_uant1ty. The effects of incomplete purge have been studied

1~ enriched in the weak sorbatc. Feeding continues until the producl 1mpunty 1n detail by Maiz and Knachci. ~

level rises to the acceptable limit. In other words. the concentration front of The ongmal Skarstrom cycle was used for a1r drymg. This process. with a

2

the strong sorbate is allowed to break through to a preassigned limit. The silica gel desiccant, was shown to reduce water content from 3800 ppm to less

idea behind the purge step JS to flush the void soaces within the bed and to than 1 ppm, with the recoverv of dry air bemg about 73%. The process

4

ensure that at least the end of the bed from which product will be withdrawn details along with the product profile are shown m Figure 3.5. The. Skarstrom