Page 102 - Pressure Swing Adsorption

P. 102

:i I

PSA CYCLES: BASIC PRINCIPLES 77

76 PRESSURE SWING ADSORPTION

RAFFINATE PRODUCT

t

Figure 3.6 Vanatmn of the blowdown stream comribut1on to the ioss of raffinate

product with feed pressure. A s1mole mass balance (assummg negligible adsorpnon of

VENT

the raffinate oroduct) yields for the fraction of the raffinate product lost m the

blowdown stream

11 + !',,11P1.GXr,.i1ir,u/LP11(Pu -i.),\\dl .. 1

'!.he prolilcs are shown for G = 2.0, /\ = 1.0 atm, ipu = 60 s, .X\, 111 = 0.95, and

Xi,J = 0.5. The numbers on the curves mdicate L / 0 rat10s.

011

FEED

/a)

suggested that the purge backwash volume (measured at the purge pressure)

should exceed the feed volume (measured at the high ooeratmg pressure) at

4

all pomts m the beds dunng each cycle m order to obtain a pure product. 1n

practice the purge-to-feed volume should generally be between one and two.

The relative contributions from blowdown and purge streams to the total loss

COL. i

of raffinate product deoend on the level of the higher operatmg pressure.

Since the product emerges at the high pressure while purgmg takes olace at

atmosohenc pressure, the actual fraction of the product stream lost as purge

1s Quite small and becomes negligible when the pressure ratio is large. On the

other hand, the contributmn from the blowdown loss mcreases with mcreas-

mg pressure, and becomes completely dominant at high ooeratmg pressure, ,~, u

as mav be seen from Figure 3.6. The improved performance of most of the

more complex cycles comes from reduction of the blowdown losses.

3.2.2 Pressure Equalizallon ! Feed

Pressurization Adsorption Pressure Slowdown Desorption Pressure

The first improvement over Skarstrom·s angina! cycle was the mtroductmn of Equalization Equatizolion

8

a pressure eaualizataon step proposed by Berlin. A schematic diagram of the

(b)

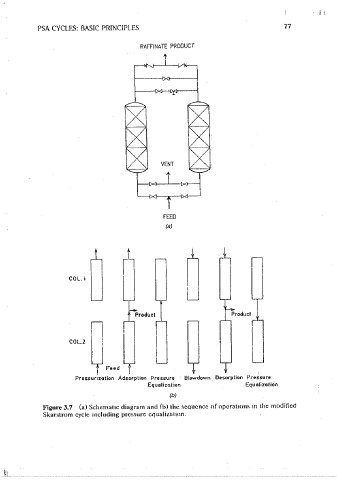

improved. process and the modified sequence of ooerat1ons are shown in

Figure 3.7. After the first bed has been purged and the second beli has Figure 3.7 (a) Schematic diagram and (b) the sequence M operations in the modified

Skarslrom cycle including pressure cqualizallon.

compklt::li the high-pressure adsorption step, instead of hlowmg down the

second hcd directly, the two beds are connected through their product enc.is

to equalize the pressure. The first bed 1s thus partially pressurized with gas

from the outlet region of the second bed. Followmg pressure equalization the

bccts arc disconnected and the first bed is oressunzcd with feed gas while the