Page 105 - Pressure Swing Adsorption

P. 105

L

!LI

80

PRESSURE SWING ADSORPTION PSA CYCLES: BASIC PRINCIPLES 81

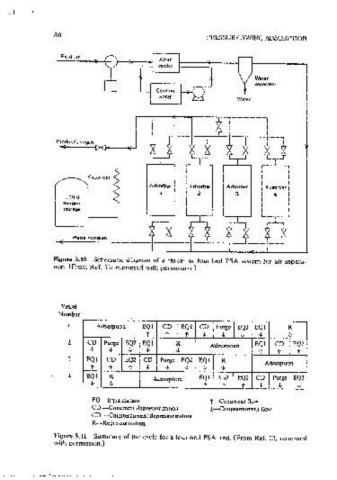

Ah:er connected to the inict of bed I. The cvcle configuration 1s summarized m

cooler Figure 3.11.

Water The idea of product reoressunzat1on was put forward for the first tune m a

separa1or very similar oateni for hydrogen puriticauon by Wagner. 14 Prcssunzat10n

Cooling

wa!er with product oushes the residual adsorbed components toward the feed end

Water

of-the adsorber, therchy enhancing the product punty. The four-hed config-

uratton allows continuous product withdrawai and eli"m1nates the use of an

empty tank for storing purge gas.

In multiple-bed systems greater conservation of energy and separative

work are achieved at the cost of a more complex process scheme. In some

Product oxyge11

large-scale hydrogen ourificat1on PSA systems uo to twelve adsorbem beds

are used.

I

,,.-~-, Vaoonzer I I

I I 3.2.4 Vacuum Swmg Cyde

Adsorber Adsorber Adsorber 1 Adsotber I

2 3 I 4 I

LiQUld I I The simplest way to understand a vacuum swmg cyctdVSC) IS to consider It

oxygen I I as a Skarstrom cycle m which the low-pressure countercurrent orodllct purge

storage I I

L_, _ _j step 1s replaced by a vacuum desorot1on. The oroduct end of the column is

t-'-z kept closed and the vacuum 1s pulled through the feed end· as shown m

Figure 3.12. In a vacuum swmg cycle, usmg the same high operating pressure

Waste n1trocien as a Skarstrom cycie, for the same product punty; the loss of the less

---1--.J

favorahly adsorbed species m the evacuation step 1s ·normally less than the

corresponding loss m the purge. The gatn Jf'l raffinate rccovcrv 1s achieved

Figure 3.10 Schematic diagram of a three~ or four~bed PSA svsiem for air separa~

t1on. (From Ref. 11; rconnted with perm1ss1on.) here at the exoense of the additional mechanical energy reQU1red for the

evacuatton steo. A significant energy savmg 1s oossible:if the cycle is operated

with the higher pressure slightly above atrnosohenc pressure and a verv low

desorption pressure. In the low~oressure (linear) range of the adsorption

isotherm it 1s the pressure ratio and not the actual high- and Jaw-pressure

Vessel

Number levels that determines the achievable ounty and recoverv. A vacuum swmg

I

Adsorption EQI CD I EQ2 CD Purge I EQ2 EQI R

t t t -1, -1, -1, -1, J, 1

2 CD Purge EQ2 EQI R Adsorption EQI CD I EQ2

.j, .j, .j, .j, .j, eo, :·~·· •o•~"-"· "~ "'□--·

t t t

EQI CD EQ2 CD Purge I EQ2 EQI R Adsorpuon

1' t 1' .j, -l, .j, -l, .j,

4 EQI R Adsorpuon EQI CD i EQ2 CD Purge I EQ2

.j, -1, t 1' t J, -1, -l,

EQ-Equalii.a.tton t-Cocurrcnl now '"" ~"""" ~ ~""""" ~

CD ---Cocurrent depressunz.at1on ,1,--Countercurrent now

CD -Countercurrent depressunzatlon

R-Repressunzauon

Figure 3.IJ Summary of the cycle for a four~bcd PSA unit. (From Ref. 13; reonnied

with permission.) Feed Blow down Vacuum Repressurization

Figure 3.12 The seouence of steps m a vacuum swmg cvcle.