Page 109 - Pressure Swing Adsorption

P. 109

:u

84 PRESSURE SWING ADSORPTION PSA CYCLES: BASIC PRINCIPLES 85

arrangement will reduce the adsorbent nroduct1v1ty and. the optimum choice used by Yang and Doong 1s shown 1n Figure J.J4_ Ccn and Yang 18 111 another

therefore depends onmarily on the value of the extract product. study repeated the same separation and demonstrated that the puntv of the

When the separation factor is low, the adsorbed Phase concentrations of extract product 1s improved further by reotacmg the cocurrent deoressunza-

the light and heavy components are comparable. The reduction in the t1on step with a cocurrent methane purge step d':onducted at the feed

concentration of the lighter species m the bed as a result of cocurrent pressure.

deoressurization may not then be sufficient to meet the ourity requirement

for the extract product. A more effective method for improving extract purity

is to purge (or rmse) the void spaces, after high-pressure adsorot1on, with the

strongly adsorbed species m the direction of the feed. 16 The effluent gas 3.4 Cycles for the Recovery of Pure Raffinate Product

during this step is produced at the feed pressure and has a feedlike compos1- in Kinetically Controlled Separations

tmn so that the stream may easily be recycled.

The ounty of the strl'ingly adsorbed comoonent depends cnt1cally on the The PSA cycles discussed so far, for both purification and hulk separatJOn,

use of cocurrent depressunzatton or purging by the more strongiy adsorbed were developed for separations based on eouilibnum sclect1v1tv. The cvclcs

species. The use of vacllum desorption 1s not particularly crucial unless one 1s used for kinetic separatmns are somewhat different. ln such systems the

dealing with strongly adsorbed species with a type I isotherm. For bulk choice of contact time is critical. Since the idea 1s to exp Iott the difference in

separations involvmg components with moderate isotherm curvature. it 1s the diffus10n rates of the adsorbing molccuies, the contact time must be short

possible to achieve high auality of both raffinate and extract products by enough to prevent the svstem from approaching equUihnum but not so shqrt

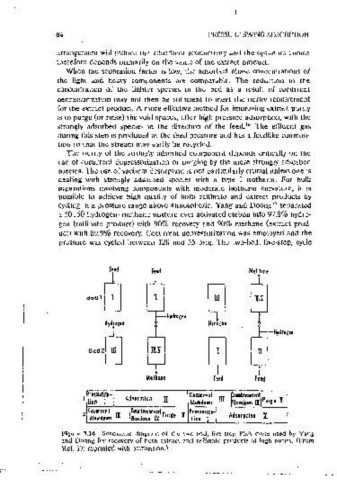

cycling fn a pressure range above atmospheric. Yang and Doong 17 separated as to preclude significant uptake. The crucial elerneiiJ.t m any kinetic seoara-

a 50: 50 hydrogen-methane mIXture over achvated carbon mto 97.8% hydro- uon 1s therefore the duration of the adsorption and desorption steos.

gen (raffinate product) with 90% recovery and 90% methane (extract prod- The only widely used commercial PSA process based on kinetic selecl!v1tv

uct) with 89.9% recovery. Cocurrent depressurizat1on was employed and the 1s air seoarat10n for nitrogen production using a carbon molecular sieve or

pressure was cycled between 120 anJ 35 os1g. The two-bed, five-step, cycle 4A zeolite adsorbent. Kinetic separation of air for nitrogen production using

Union Carbide RS~'I0 molecular sieve (modified 4A zeolite) has been investi-

1

gated by Shin and Knaebe!_l' In a recent study Kapoor and Yang 211 have

shown that methane-carbon dioxide separation (from landfill gas or effluent

d Methane

gas from tertiary oil recovery) using carbon moiecular sieve is another

~ s applied to a kinetic PSA separation, such a cvcle 1s far from ideai. A ma,or

prospective candidate for kinetic seoarat1on.

Although with properly seiccted ~tep times the Bkarstrom cycle can be

Hrdrogen disadvantage is that the slowly diffusing raffinate product would be contmu-

Hy roe en ously adsorbed during the purge step. This difficulty can be avoided bv use of

Hydrogen vacuum desorot1on or by using a modified form of "self-ourging·· cvcle.

~ n 3.4.1 Self-Purging Cycle

21

Methane feed Fied Eouilibnum and kinetic data for the sorpt1on of oxygen and nitrogen on the

Bergbau-Forschung carbon molecular s1eve

are shown in Figure 3.15 and

summarized in Table 3.2. It 1s apparent that there is little difference in

ressuma- Cocurrent m

1 /wsorplion ][ eQuilibnum but a large difference m diffus1v1ty, with oxygen being the more

tion I Slowdown rapidly adsorbed species. The high~pressure raffinate product in the carbon

Cotii,rrent ill y rressunu

2 Adurption [ molecuiar sieve process 1s therefore nitrogen. In such a system purging with

Blow down tion I

nitrogen to remove the faster diffusing oxygen from the bed (as m the

Figure 3.14 Schematic diagrnm of the two-bed, five-step PSA cvcle used by Yang Skarstrom cycle) ts undesirable smce, as well as wasting product, a certain

and Doong for recovery of both extract <me! ramnntc proctucts at high punty. (From fracoon of the slowiy diffusing nitrogen will be adsorbed, thus reducing the

Ref. 17; reprmted with perm1sS1on.) capacity for oxygen dunng the next adsorot1on step. The earlier kinetic