Page 108 - Pressure Swing Adsorption

P. 108

,i 1

82 !'HESS\ IHE SWING ADSORPTION PSA CYCLES: BASIC PRINCIPLES 83

cycie will therefore be advantageous over a Skarstrom cycle if a low-pressure Liquide cycle also produces a mtrogen-nch stream {96.3% nitrogen at 58%

product 1s acceotablc. However, this a(lvantage m operating cost 1s to some recovery) from the evacuation step.

extent offset by the increased capital cost ansmg from the increased size of The gain m raffinate product recovery obtamed here resuits from two

tile equipment.

1morovements over the Skarstrom cycle. The recovery advantage of vacuum

The idea of vacuum regeneration was onginally proposed hy Guerin de regeneration over purge has already hecn discussed. Jn additmn, the cocur-

1

Montgarcuit and Domine 1n a patent assigned to Air Liquidc.· There arc, rent deoressunzation through an evacuated chamber actually conserves part

however, several differences between the pressure swmg cycie proposed by of the raffinate product that would have otherwise been Jost durmg evacua-

Montgareuil and Demme and the simplified vacuum swing cycle shown rn tion. It 1s important to note that the gam m the raffinate recovery from

Figure 3.12. Depending on the nalun: uf lhc gas mixture to he sepan.,tcd, the cncurrent dcprcssurizai1on nwy not he achieved .if this step, 1s used 1n

Air Liquide ·process can vary in the number or adsorbcm beds, the type of combination with (product) purge rcgcncratJ(Hl. Cocurrcni dcprcssur1zation

oed assoc,atton, and the scheme of cyclic operation, as well as in other contaminates the product encl with the more strongiy adsorbed s.occ1cs. Suh

operat111g conditions. The number of beds can vary from one to six or more. and Wankal 15 have shown that depending on the amount of the more

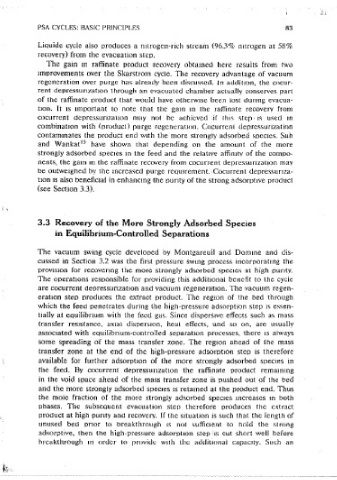

A two-bed illustration of this process 1s given m Figure 3. 13. Bed ! . is strongly adsorbed species m the feed and the relative affimtv of the comoo-

pressunzed to the high opcratmg pressure by mtroducmg a compressed feed nents, the gam m tl1e raffinate recovery from cocurrent depressunzation may

gas from the 111lct end. The mlct end 1s then closed and the gas ,s expanded be outweighed by the mcreased purge requirement. ,Cocurrent depressunza-

cocurrently through bed 2 and the effluent from this bed 1s recovered as t1on is also beneficial in enhancing the ounty of the strong adsorptive product

raffinate product. When the pressure m heel 1 reaches a predetermined (see Sectmn 3.3).

intermediate pressure, the discharge end of bed i 1s closed and the vacuum

line (located at the middle of the t,ed) 1s opened for regeneration. At the

same time the mlet end of bed 2 is ooened to high-pressure feed stream, with

the discharge end closed. for rcprcssunzation. The major disadvantage of the 3.3 Recovery of the More Strongly Adsorbed Species

Air Liquide cycle is that the product 1s delivered at a low (subatrnospheric) in Equilibrium-Controlled Separations

oressure. (Air separation usmg this cycle produced 98% oxygen at 51 %

recovery. This result was ·markedly supenor to the performance of the The vacuum swing cycle developed by Montgareuil and Dom1ne and dis-

comoetmg Skarstrom cycle for the same separation. Additionally, the Air cussed m Section 3.2 was the first pressure swing process incorporating the

prov1s1on for recovering the more strongly adsorbed species ar high ountv.

The ooerat1ons responsible for providing this additional benefit to the cycie

COMPRESSED AIR

) are cocurrent deoressunzat10n and vacuum regeneration. The vacuum regen-

eration step produces the extract product. The region of the bed through

which the feed penetrates during the high-pressure adsorption step 1s essen-

tially at equilibrium with the feed gas. Since dispersive effects such a~ mass

transfer resistance, axial dispersion, heal effects, 'and so on, are usually

associated with eauilibnum-controlled separation processes, there 1s always

VACUUM some spreading of the mass transfer zone. The region ahead of the mass

transfer zone at the end of the high-oressure actsorot1on step is therefore

available for further adsorot1on of the more stron,giy adsorbed soec,es in

the feed. By cocurrent depressunzat1on the raffinate product remaining

in the void space ahead of the mass transfer zone is pushed out of the bed

and the more strongly adsorbed species 1s retamed at the product end. Thus

the mole fraction of the more strongly adsorbed species increases 1n both

ohases. The subsequent evacuation step therefore produces the extract

0 RICH product at high purity and rccovcrv. If the situation is such that the length of

2

GAS unused bee.I onor to breakthrough 1s not sufficient to hold the strong

Fi~urc 3.13 Schematic diagram of 1hc two-hcd Ai1 Liquide PSA system. (After adsorptive, then tile high-pressure adsorption step l1s cut short well before

Montg:1n.·uil and Dommc·i) hrcakthrough m order to provide with the ~1dditmnai capaclly. Such an