Page 100 - Pressure Swing Adsorption

P. 100

74 PRESSURE SWING ADSORPTION PSA CYCLES: BASIC PRINCIPLES 75

ORY AiFI OUT

40 PS1G. a.~ sent

CHECK VALVES

Col

REGENEFIA.TION FLOW VA.LVE

O.~ SCFM i---<;.,.--

ProdlJCi

DFIV1NG CHAM8EFIS A 6 8

EACH CHAIA8ER•

l LS. M08lL6EAOS

Col 2

Pre~ruruauon Feed Slowdown Purge

·k:17 ~/,1~~----j) MINUTES AS Sl-lCWN

4 • WAY SOLENOiO VALVE:

I

J.NQ REPEAT

0 0.3 • T 0.5 • T 0.8 • T T > 110 VAC J M1NUT£S OTI--IER POStTION

A(CYCL£ TIMER WET ;:.1R IN

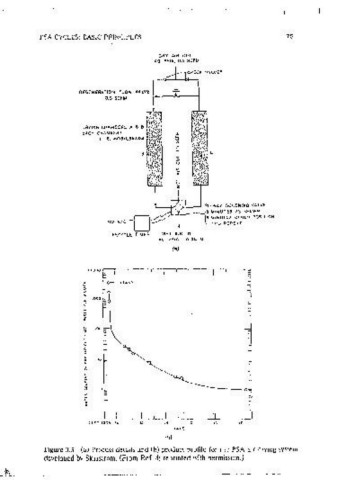

Fi~1ire 3.4 The sequence of steps Ill the hns1c Skl\rstrom PSA cvc\c. <10 PSIG. 1.0 SCFl.1

/a)

cycle 1s still widely used for small-scale· air drying. and this cycle has also

oroved successful for other similar separations where the 1rnourities are , ~ f,<.R f ~

present at low concentration and the selectivity of the adsorbent 1s high. 0 j ·1r

a

Under these conditmns the raflinate product behaves as a nonadsorbing .

inert. .

Oxygen oroduction from air usmg 5A or 13X zeolite as the adsorbent 1s an . ~\ ~

example of a bulk separation. The oreferennally adsorbed soec1es (nitrogen) '

,

is present at a relatively high concentration level, and there 1s significant 0 •oor

coactsorpt1on of the Jess strongly adsorbed species (oxygen). Such a seoara- 0

0

t1on can be achieved usmg the Skarstrom cycle, but a reasonably pure •

raffinate product can be achieved only at low fractional recovery, making the ' " ~

ii

economics unattractive. In Skarstrom's ongmal exoenments usmg a 13X ~

zeolite adsorbent, a 90% pure oxygen product was achieved only at a , l

6

recovery of 10%. The separation factor for this particular adsoment appears ,

8

to have l)een rather low (2.0), and a somewhai hetter performance can he ~

expected with the higher separation factors (3-3.5) typically ot,tamed with a •

well-dehydrated zeolite. 7 However, to 1morove the econom1cs, further en-

hancement of the recovery-purity profile is obviously desirable. HP T !9~6 <z ,.

In a Skarstrom cycie the coiumn effluent during the blowdown and purge " OUE " " "

steps 1s normally waste gas (nch m the more strongly adsorbed species but (b)

containmg a significant fraction of the less strongly held species). Skarstrom

Figure 3.5 (a) Process details and (b) product profile for the PSA air ctrvmg svstem

develooed bv Skarstrom. (From Ref. 4: reprinted with oerm1ss1on.)