Page 146 - Primer on Enhanced Oil Recovery

P. 146

136 Primer on Enhanced Oil Recovery

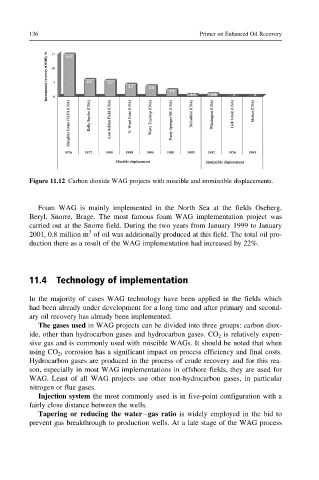

Figure 11.12 Carbon dioxide WAG projects with miscible and immiscible displacements.

Foam WAG is mainly implemented in the North Sea at the fields Oseberg,

Beryl, Snorre, Brage. The most famous foam WAG implementation project was

carried out at the Snorre field. During the two years from January 1999 to January

3

2001, 0.8 million m of oil was additionally produced at this field. The total oil pro-

duction there as a result of the WAG implementation had increased by 22%.

11.4 Technology of implementation

In the majority of cases WAG technology have been applied in the fields which

had been already under development for a long time and after primary and second-

ary oil recovery has already been implemented.

The gases used in WAG projects can be divided into three groups: carbon diox-

ide, other than hydrocarbon gases and hydrocarbon gases. CO 2 is relatively expen-

sive gas and is commonly used with miscible WAGs. It should be noted that when

using CO 2 , corrosion has a significant impact on process efficiency and final costs.

Hydrocarbon gases are produced in the process of crude recovery and for this rea-

son, especially in most WAG implementations in offshore fields, they are used for

WAG. Least of all WAG projects use other non-hydrocarbon gases, in particular

nitrogen or flue gases.

Injection system the most commonly used is in five-point configuration with a

fairly close distance between the wells.

Tapering or reducing the water gas ratio is widely employed in the bid to

prevent gas breakthrough to production wells. At a late stage of the WAG process