Page 147 - Primer on Enhanced Oil Recovery

P. 147

Water altering gas injection 137

(A) Gas pipeline or Gas

gas producing well

Second compression

Gas

stage

Crude First compression

stage

Separators and

storage

Mixer

Water

Pumping Water/gas mixture

station

Injectic

Water well

well

(B)

Gas

Water/gas

Crude

mixture

Separators and

storage Mixer Compression

stage Water/gas mixture

Water

Injection

well

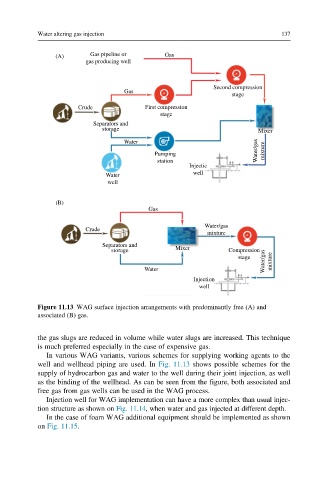

Figure 11.13 WAG surface injection arrangements with predominantly free (A) and

associated (B) gas.

the gas slugs are reduced in volume while water slugs are increased. This technique

is much preferred especially in the case of expensive gas.

In various WAG variants, various schemes for supplying working agents to the

well and wellhead piping are used. In Fig. 11.13 shows possible schemes for the

supply of hydrocarbon gas and water to the well during their joint injection, as well

as the binding of the wellhead. As can be seen from the figure, both associated and

free gas from gas wells can be used in the WAG process.

Injection well for WAG implementation can have a more complex than usual injec-

tion structure as shown on Fig. 11.14, when water and gas injected at different depth.

In the case of foam WAG additional equipment should be implemented as shown

on Fig. 11.15.