Page 159 - Primer on Enhanced Oil Recovery

P. 159

Chemical EOR 149

and usable rheological properties. Some projects used biopolymer Xanthan (it is

produced by bacteria Xanthomonas campestris). The polymer has good stability in

salted and high hardness water, it is reasonably resistant to mechanical damage but

stable only to approximately 90 C. On one side it is easily digested by other bacte-

ria, which is not so good for the application, but, on the other side, as it destroyed

by the bacteria it is counted as biodegradable and is environmentally friendly.

12.1.3 Implementation Technology

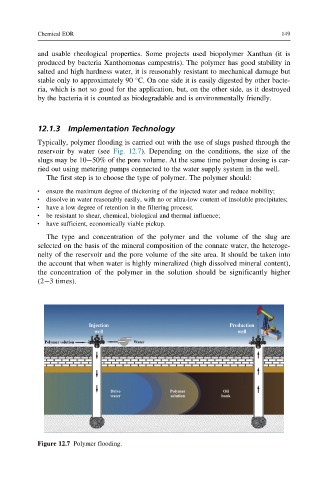

Typically, polymer flooding is carried out with the use of slugs pushed through the

reservoir by water (see Fig. 12.7). Depending on the conditions, the size of the

slugs may be 10 50% of the pore volume. At the same time polymer dosing is car-

ried out using metering pumps connected to the water supply system in the well.

The first step is to choose the type of polymer. The polymer should:

ensure the maximum degree of thickening of the injected water and reduce mobility;

dissolve in water reasonably easily, with no or ultra-low content of insoluble precipitates;

have a low degree of retention in the filtering process;

be resistant to shear, chemical, biological and thermal influence;

have sufficient, economically viable pickup.

The type and concentration of the polymer and the volume of the slug are

selected on the basis of the mineral composition of the connate water, the heteroge-

neity of the reservoir and the pore volume of the site area. It should be taken into

the account that when water is highly mineralized (high dissolved mineral content),

the concentration of the polymer in the solution should be significantly higher

(2 3 times).

Figure 12.7 Polymer flooding.