Page 175 - Principles of Catalyst Development

P. 175

CATALYST CHARACTERIZATfON 163

ENCAPSULA TlON

SUPPORT

METAL

CRVST AlllTE

PORE TRAPPING

PORE

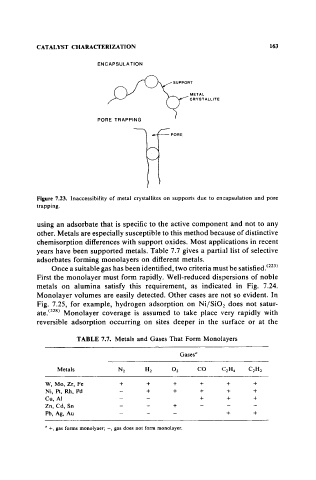

Figure 7.23. Inaccessibility of metal crystallites on supports due to encapsulation and pore

trapping.

using an adsorbate that is specific to the active component and not to any

other. Metals are especially susceptible to this method because of distinctive

chemisorption differences with support oxides. Most applications in recent

years have been supported metals. Table 7.7 gives a partial list of selective

adsorbates forming monolayers on different metals.

Once a suitable gas has been identified, two criteria must be satisfied. (223)

First the monolayer must form rapidly. Well-reduced dispersions of noble

metals on alumina satisfy this requirement, as indicated in Fig. 7.24.

Monolayer volumes are easily detected. Other cases are not so evident. In

Fig. 7.25, for example, hydrogen adsorption on Ni/Si0 2 does not satur-

ate.(228) Monolayer coverage is assumed to take place very rapidly with

reversible adsorption occurring on sites deeper in the surface or at the

TABLE 7.7. Metals and Gases That Form Monolayers

Gases"

Metals N2 H2 O2 CO C2H 4 C2H2

W, Mo, Zr, Fe + + + + + +

Ni, Pt, Rh, Pd + + + + +

Cu, Al + + +

Zn, Cd, Sn +

Pb, Ag, Au + +

" +, gas forms monolyaer; -, gas does not form monolayer.